Barley intensification

CLOSE COST ANALYSIS REQUIRED

AT THE 2016 harvest, we saw much less barley come to market in the Guelph area. Many Ontario barley growers were down on average yields, but there were still a lot that were above average. West of Guelph, for example, there was almost a direct line of growers who got rain and they got an awesome yield. There may be small shortages in some areas, but look out, the county over may have seen a surplus.

Grain Farmers of Ontario reports 34,886 tonnes were sold between May 1 and October 31. Nearly 5,800 tonnes of this was sold in Grey County and more than 4,300 tonnes sold in Wellington County. Bruce, Dufferin, and Dundas counties saw more than 2,000 tonnes sold during the same period. Meanwhile, less than 100 tonnes were sold in Elgin, Haldimand, Halton, Hamilton, Hastings, Middlesex, Niagara, Nipissing, and Thunder Bay.

INTENSIVE MANAGEMENT

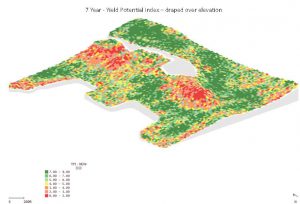

Undoubtedly, weather was a major factor this past year; but we continue to see that, if managed properly, barley has great yield potential. Historically, farmers grow their 30 or 40 acres of barley because they need feed, and they won’t manage it as intensely as other crops. Farms that are 100% cash crops rotate barley in because they didn’t get winter wheat planted — we saw that for two years in a row, when we had tougher fall seasons in 2013 and 2014 to get wheat in the ground. The latest estimate of Ontario’s 2016 fall wheat acreage is roughly 850,000 acres, so perhaps we’ll see more of this again next year. In previous years, we knew this was happening a small amount because of the surplus we saw in barley during those years. The farmers who micromanaged like they did all their other crops, adopting aggressive fertilizer programs, fungicides, and everything else — it was incredible to see the yields they could get.

The other impact more of these growers will have on barley markets is, farmers that are growing 5,000 acres of corn and soybeans won’t grow it if they don’t have a contract set up ahead of time. Contracts are where we are heading with barley now. It’s becoming a crop that you wouldn’t grow without knowing you had a buyer to take it, sort of like soft white winter wheat. If you manage it properly, and get the deal made ahead of time, we are seeing farmers do well with the crop. Heading into a harvest with a plan is a much wiser decision for any barley grower and helps both farmers and marketers in the long run.

COST OF PRODUCTION

Part of your focus on marketing barley is making sure you can actually produce enough. The other part is making sure you can get your money back out of it, which is another thing serious cash crop farmers will do when they get into barley.

When you calculate cost of production for barley, it isn’t surprising people don’t think of barley as a cash crop. The Ontario Ministry of Agriculture, Food and Rural Affairs offers sample costs of $269.25/acre in the 2017 Field Crop Budget in order to produce 1.5 tonnes per acre in a 2,800 heat unit or less zone. In zones above 2,800 heat units, that drops to $257.10 per acre. However, neither of these budgets include land costs or storage valuation because of the wide variation across the province. Fungicide is also typically a justified expense, but it is left out of these general calculations too. With those kinds of expenses, depending on the heat unit zone where you farm, you will have to get at least $171.40 or $179.50 per tonne just to break even.

For growers in lower heat unit zones, growers with very high land costs, or growers who simply can’t get more than one tonne per acre of yield, this may mean that buying the barley that you usually grow for feed would be a better deal for you.

That said, we are seeing more and more farmers value straw for much more. Be sure to take into consideration whether or not you are spreading the straw back on your fields or if you are baling it. You should be adjusting your agronomy practices and the affected expenses accordingly.

Jeff Robinson is a grain merchandiser for Woodrill Farms Ltd. •