N application in corn

RESEARCHING PRECISION AGRICULTURE STRATEGIES

WHAT’S THE BEST stage to apply nitrogen (N) in corn? What’s the right amount of N to apply? Can variable rate nutrient application increase corn yields? Ontario corn growers would like the answers to these questions and Grain Farmers of Ontario has partnered with Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) corn industry program lead, Greg Stewart, and his OMAFRA team to lead a two-year research project evaluating the best timing of N application in corn and how the timing affects variable rate nutrient application.

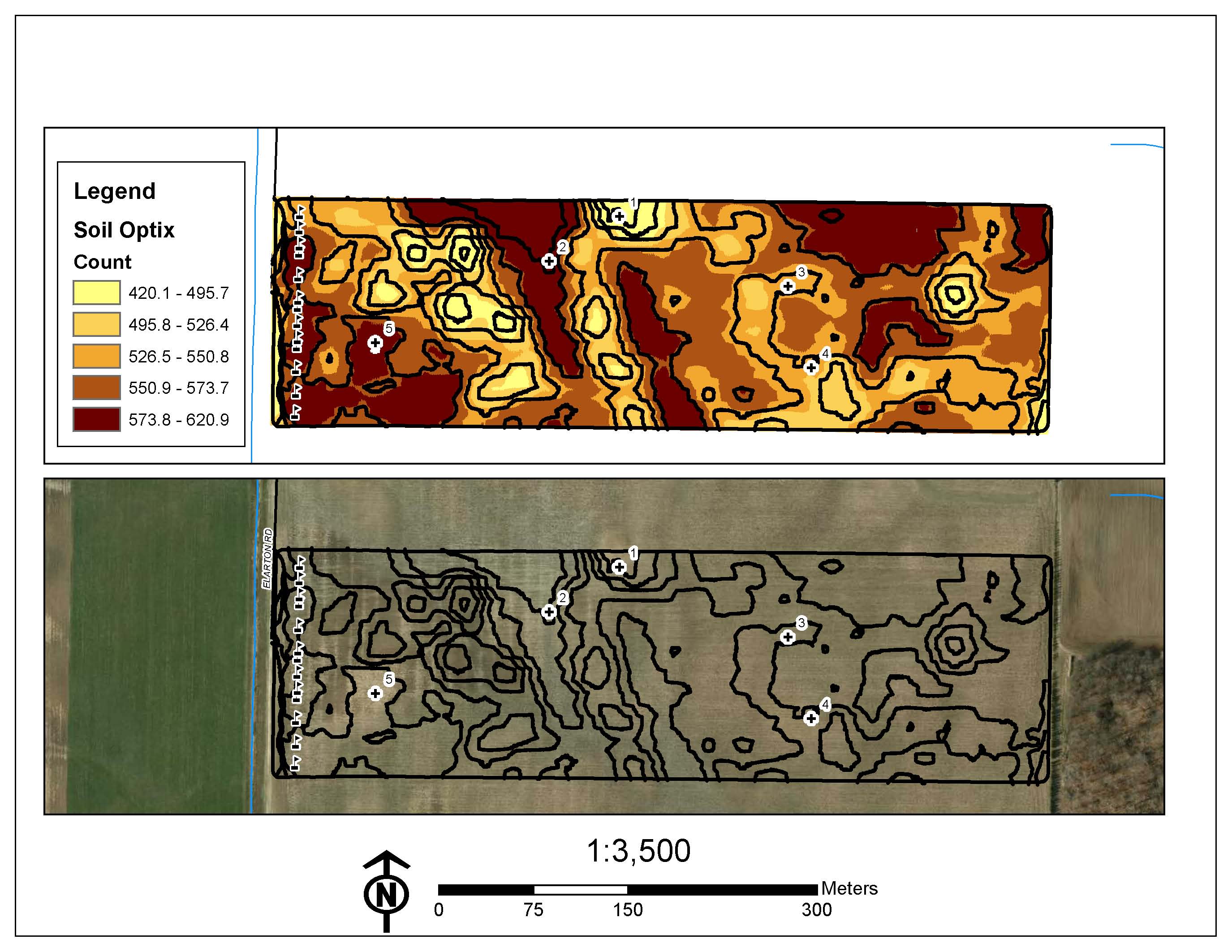

PHOTO: BARRY RAYMER PRACTICAL PRECISION INC., DRIVES ACROSS THE FIELD TAKING MEASUREMENTS WITL SOILOPTICSTM WHICH ARE LATER USED TO GENERATE NUTRIENT MAPS.

Corn growers already know timing and application rates of N are key to maximizing yield. New to the already complex equation are variable rate nutrient applications. That is why the team is combining the research of three N application timings and three variable rate approaches. “We want to determine if any of the timing options — pre-plant, sidedress, or above waist height — show a significant advantage to making variable rate N recommendations,” says Stewart. The study includes three precision agriculture tools for application — SoilOptix™ mapping systems, nitrate testing, and the optical sensing technology, GreenSeeker.

PHOTO: RAW COUNTS DATA GENERATED BY SOILOPTIXTM

Variable rate nutrient application, a form of precision agriculture which applies different rates of fertilizer to different parts of a field, is growing in popularity. The team is leading the project to find a way to help Ontario growers utilize crop inputs, like N, more effectively and efficiently. Stewart explains, “the challenge with this new approach is how difficult it is to develop a prescription or system for N application and prove whether or not it works.” He expects this project will help address these concerns. “And of course, the overall goal of the research is to find a way to improve overall productivity, or yield, by maximizing economic returns on variable rate N application,” he says.

THREE DIFFERENT APPLICATION WINDOWS, THREE DIFFERENT TOOLS

“The challenge with N application, no matter when it’s applied, is not to lose it,” says Stewart. “Factors like heavy rainfall or leaching cause N loss through the soil, reducing the amount available for corn uptake and lowering overall yield.” And since corn does not start using N in significant quantities until it is knee high, or after June 20 in Ontario, he explains, there is interest in finding new ways to apply N in later growth stages to reduce the chances of losing it before the crop really needs it.

Most N in Ontario is applied before corn planting or pre-plant. Stewart notes N is applied to approximately 20 per cent of Ontario corn acres at sidedress time, when N is injected between rows at the six-leaf stage.

There is increasing interest in applying N just before plant demand is at its highest. Advanced technology has opened up a new nutrient application window in corn, beyond waist height. “Creating a growing environment where the right amount of N is on demand for the crop will maximize yield and reduce the strain on a grower’s bottom line,” says Stewart, who is interested in learning more about this new application timing. “But application rates are important too, that’s why we are combining these two factors to evaluate the importance of timing versus variable rate application strategies.”

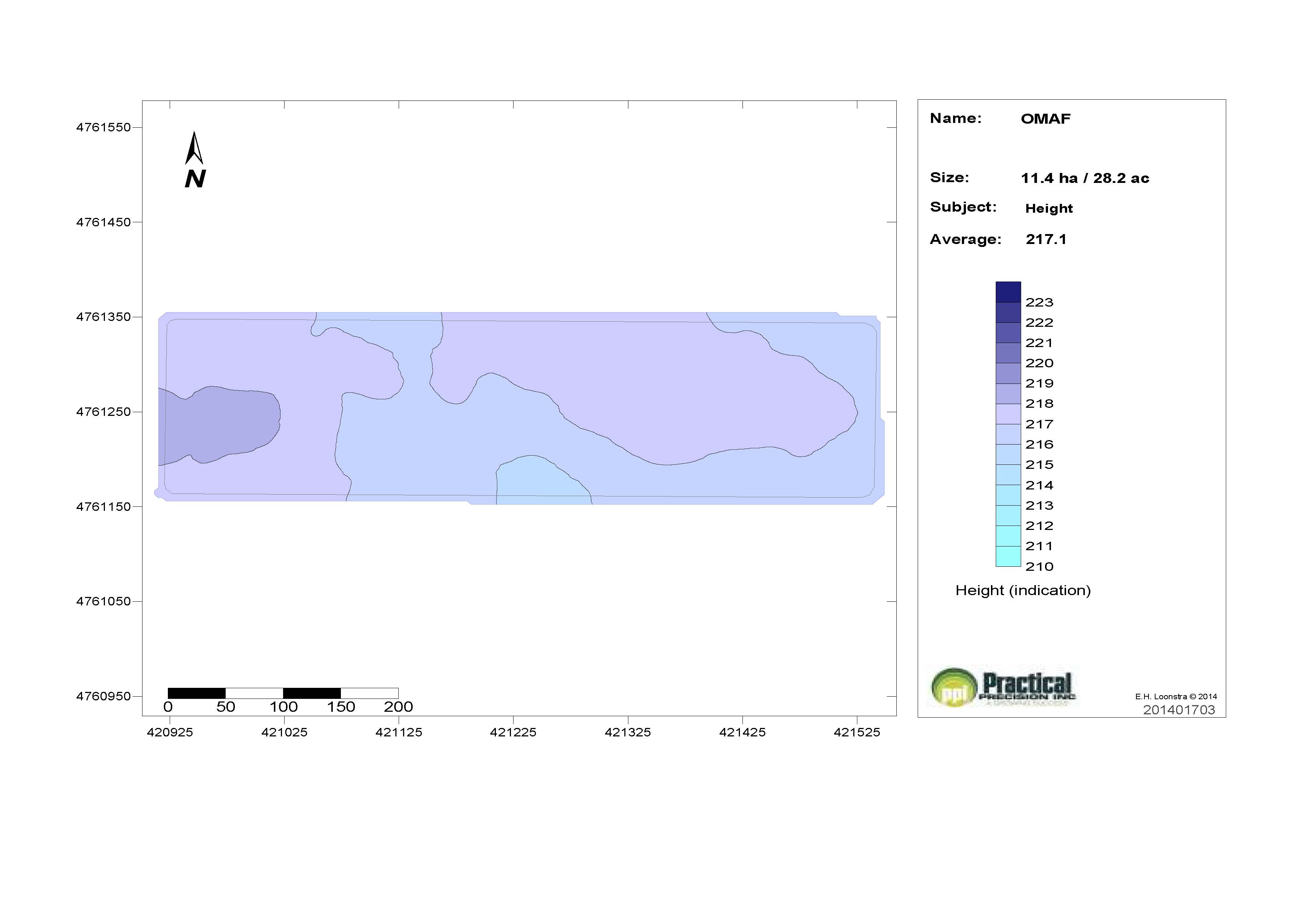

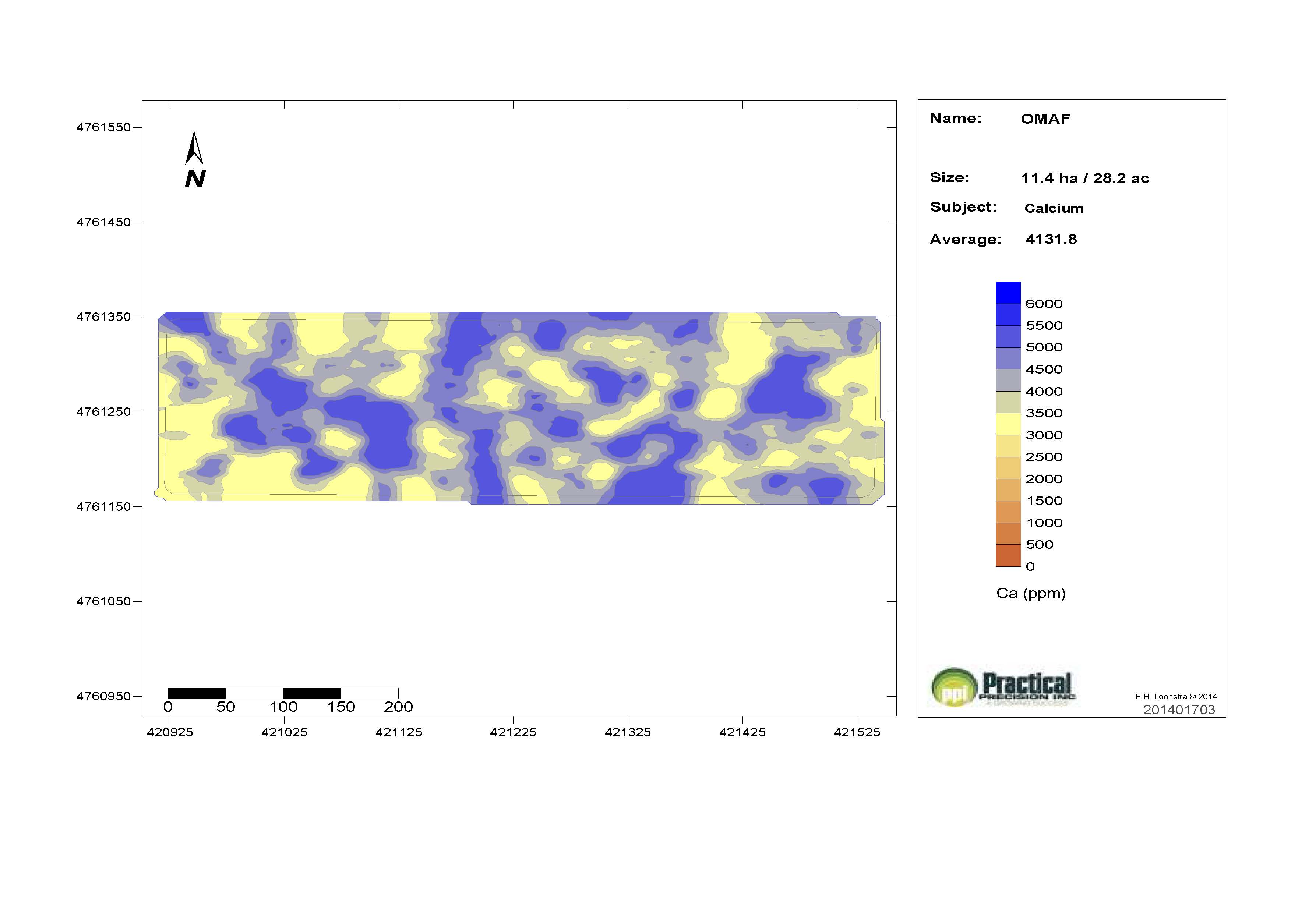

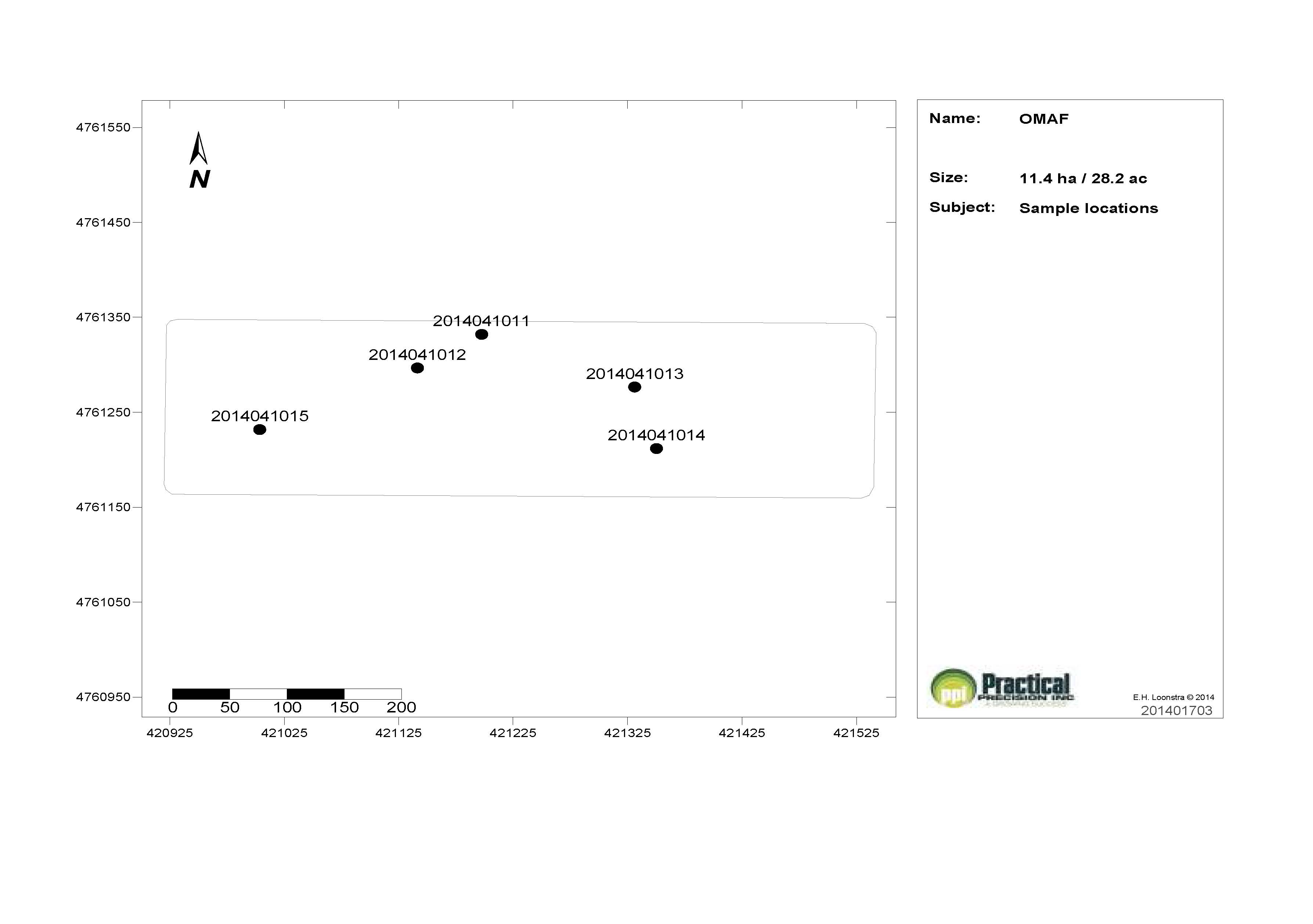

Three site locations across Ontario in Langton, Forest, and Brucefield have been set up to test the three N application windows — pre-plant, sidedress, and above waist height. The varied timing means application rates are determined differently and the OMAFRA team are using a site-specific approach to calculate these variable application rates.

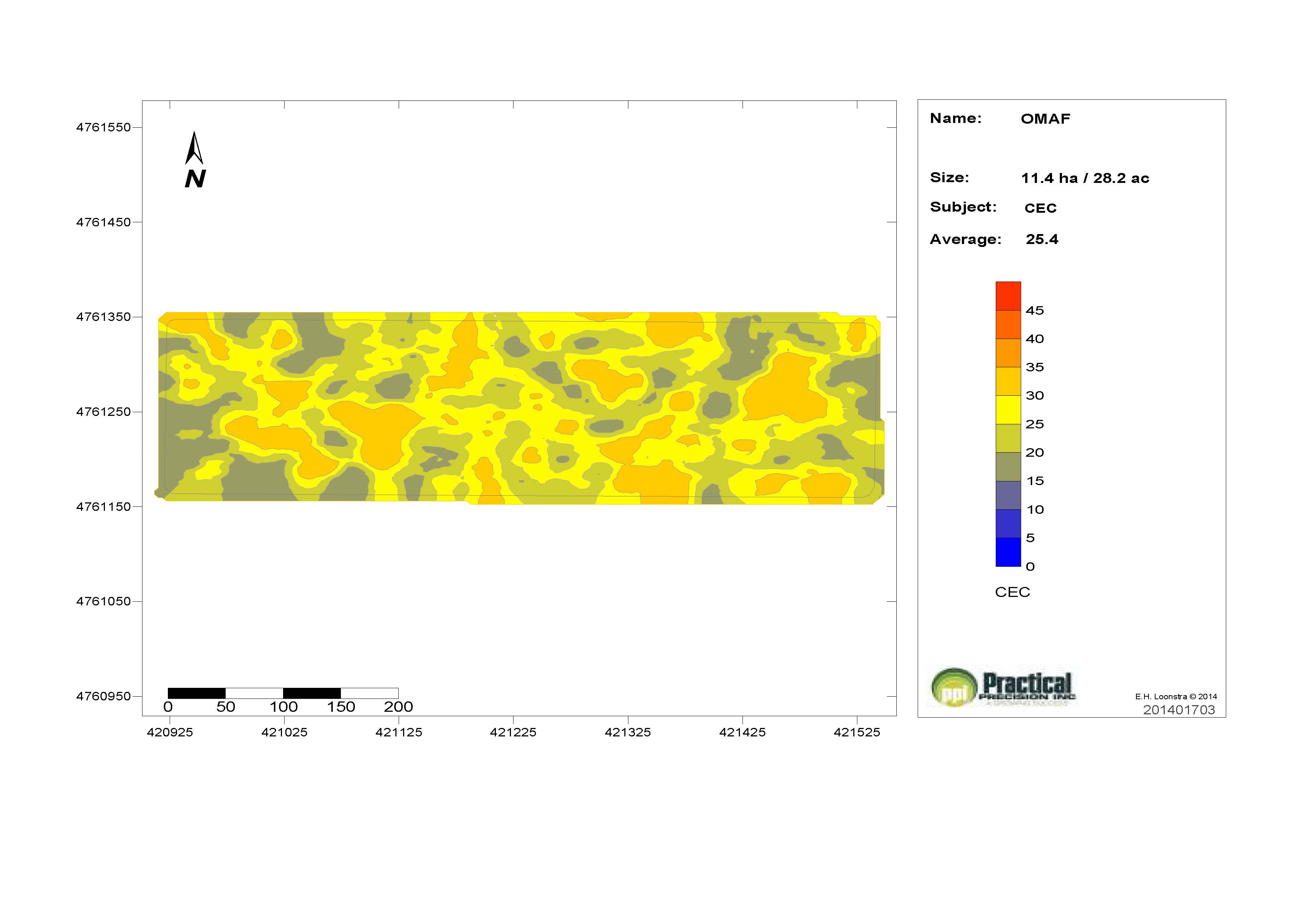

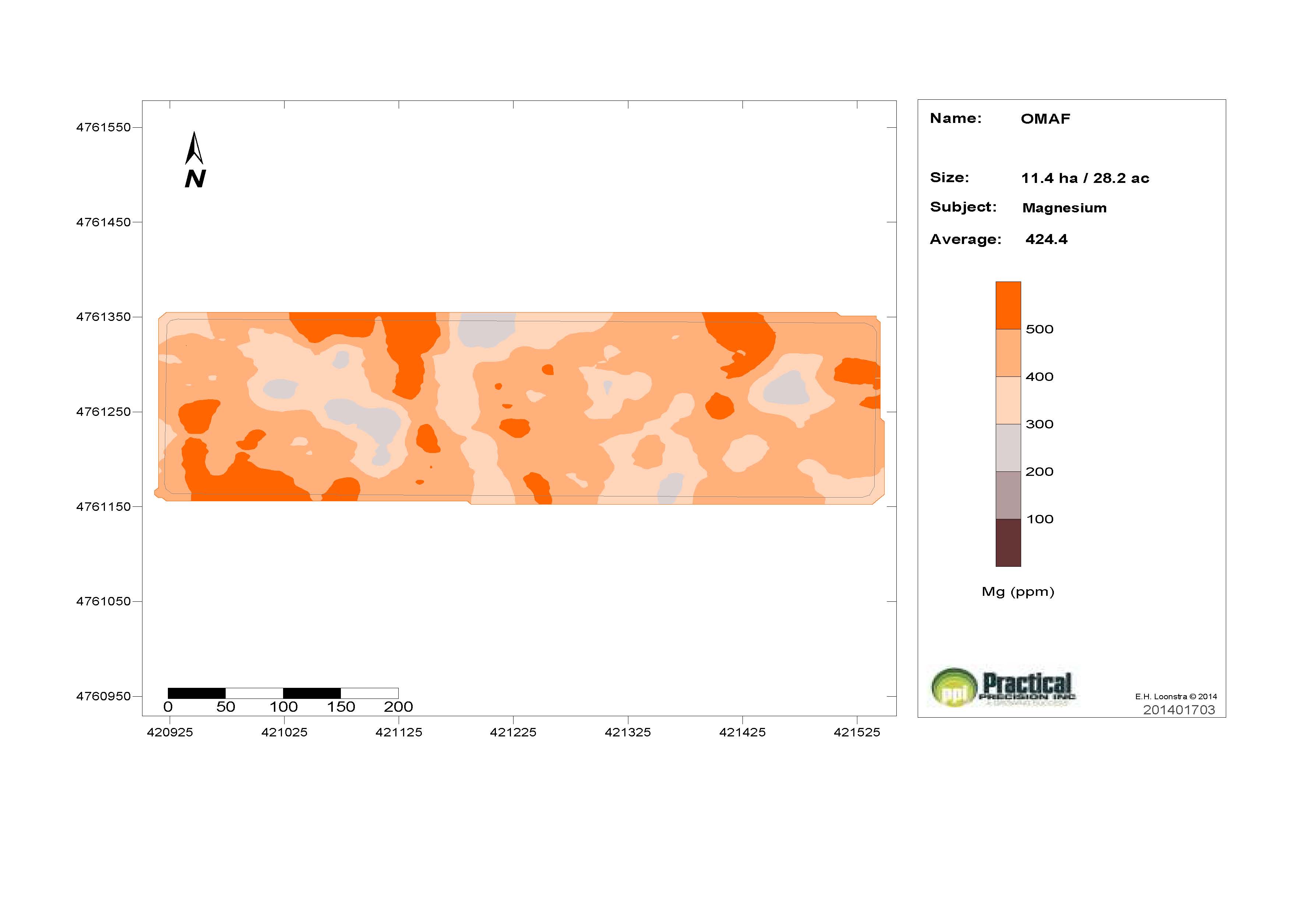

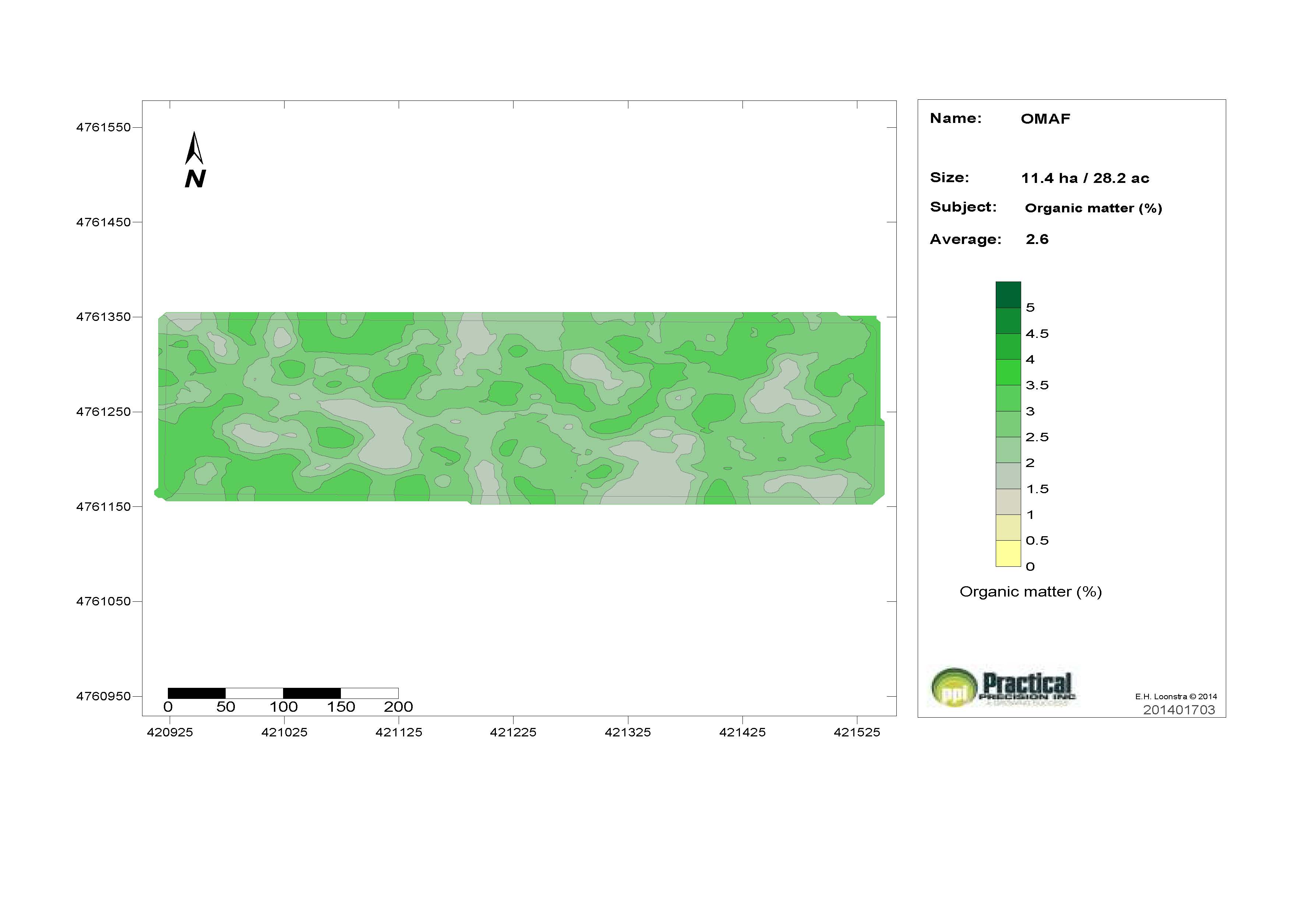

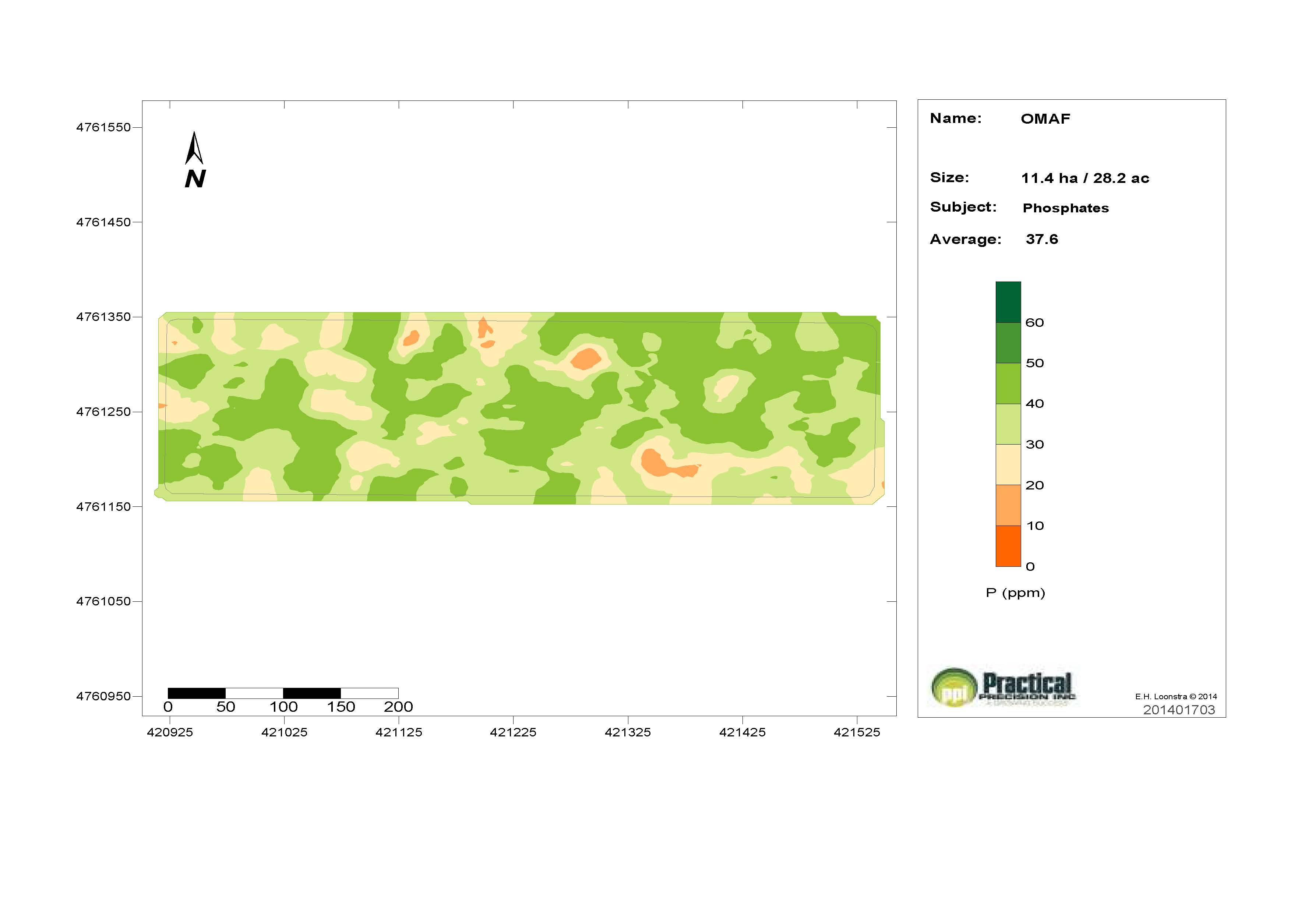

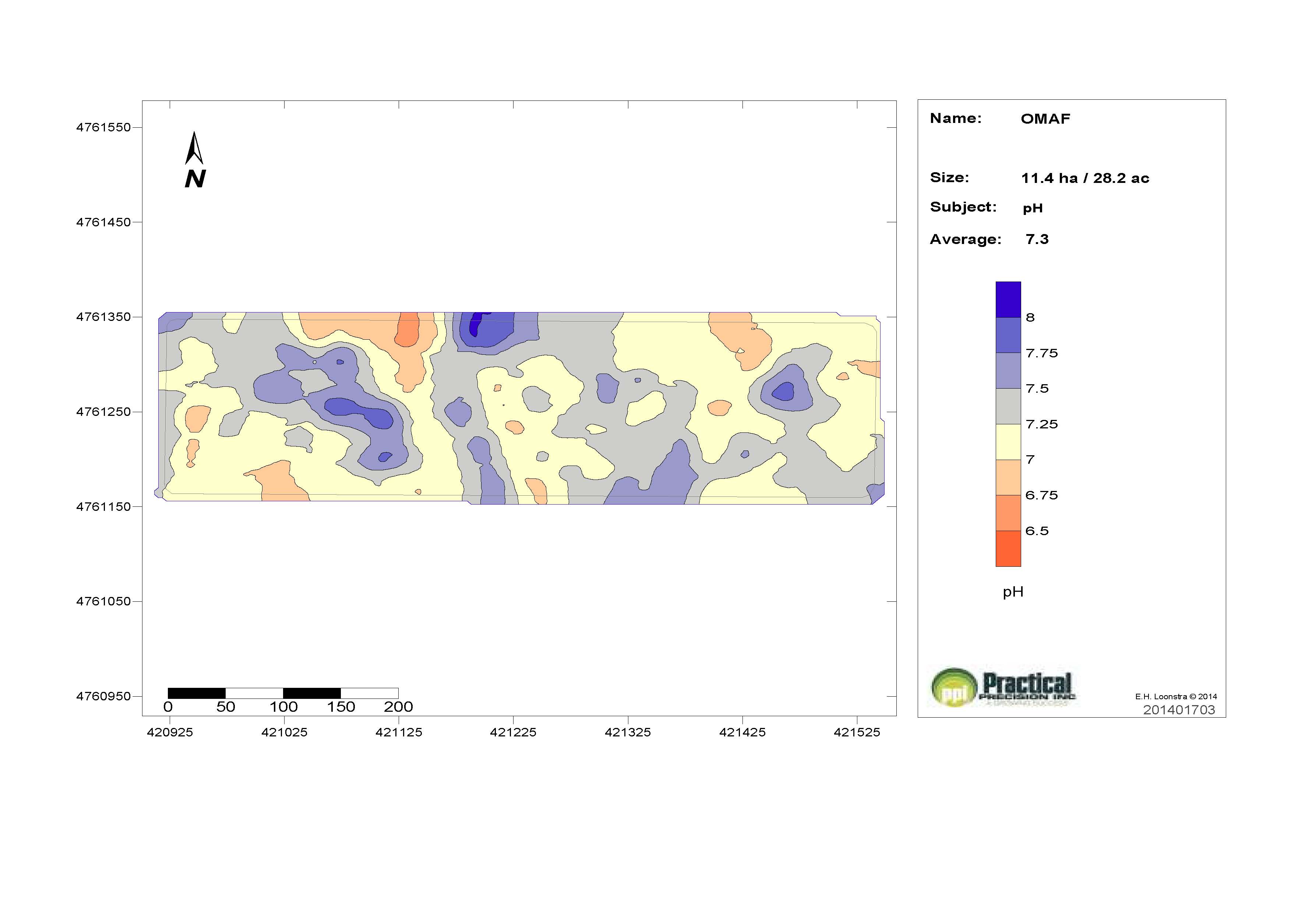

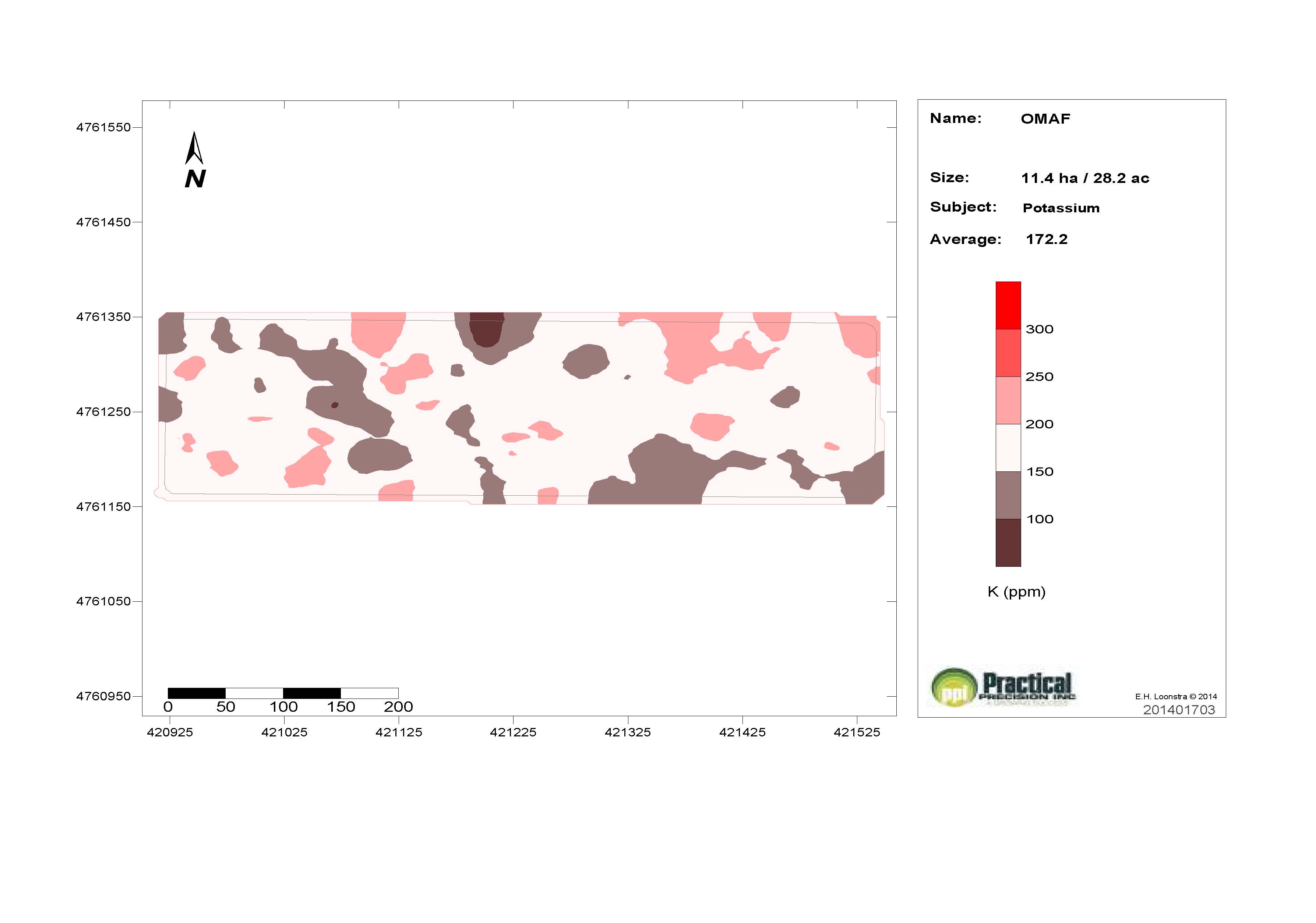

Pre-plant rates are determined by maps, since it is hard to sample the soil at that time of year, explains Stewart. To evaluate pre-plant variable N application rates, a map-based model is used, dividing each field into zones and evaluating soil properties like organic matter, yield trends, and soil texture. A new digital high resolution point mapping system, SoilOptix™, is being used to measure soil stability and topography at high density point levels to build a prescription for varying N application levels across fields.

Knee-high or sidedress N application rates are determined by nitrate testing to measure the amount of nitrogen already in the soil. This approach aims to replenish N in soil that may have been lost from dentrification or leaching. Multiple testing points, set up in zones across the fields, determine variable N application rates.

“Evaluating N rates in corn at waist height, or higher is more difficult because it’s still a new area for growers,” says Stewart. That is why he is relying on GPS and the innovative optical sensing technology of the GreenSeeker to measure the crop’s needs. Using the GreenSeeker and sensors mounted on sprayer booms of high clearance application equipment, the team can measure plant nutrient needs based on the reflection, or greenness, of plants within specific field zones. The system then accurately applies N in exactly the amount needed per field production zone.

BRINGING THE BENEFITS BACK TO THE GROWER

“Using variable rate nutrient application, we can apply N where the corn will respond the best and reduce rates where it doesn’t need it,” says Stewart. “This site-specific approach means growers could apply, on average, more or less N across a field, but place it where it makes the most agronomic sense.”

Combining the ability to apply N where the crop needs it most, with the knowledge of the best application timing, or corn growth stage could provide growers with the best chance of variable rate success. And that is just what Stewart hopes to achieve. “With these results, growers will realize economic and environmental benefits of precision agriculture tools.”

PRECISION N APPLICATION TECHNOLOGY

| SoilOptix™ |

| The digital high-resolution top soil mapping system SoilOptix™ was designed in the Netherlands and is the only one of its kind in North America. “The system works as a paint brush, connecting the dots to generate advanced maps,” says Paul Raymer, president of Practical Precision, a precision agriculture technology company in Tavistock, Ontario.

Measuring the soil’s naturally emitted radiation every five to 10 feet, SoilOptix™, uses this raw information as a base line to help mitigate human error that can be found with traditional soil sampling. In addition to analyzing the soil for traditional properties, this system also creates a highly accurate topography model that indicates different soil types and elevation levels in a field. The key strength of this tool is identifying textural based properties like percentages of clay and sand that can be translated into water influencing properties. “The end result is a high resolution digital point map that provides growers with more information than ever about their fields and soil qualities,” says Raymer. “The high density point maps can be imported in popular agricultural GIS software programs because one of the fundamental purposes is to provide foundational information to build prescriptions for variable rate seeding and nutrient levels.” |

| GreenSeeker |

| The GreenSeeker brings together GPS and optical sensing technology to generate another set of data, influencing the precision application of nutrients in corn like N. Designed for use on high clearance equipment, sensors can be mounted on the booms of most sprayers and spreaders to enable on-the-go variable rate application of sidedress N.

The GreenSeeker uses the plant instead of the soil to verify the amount of nitrogen available in the plant. The system measures the light reflected off the leaves; the chlorophyll content, (or greenness) of the plant is an indirect indicator of its N requirement. The system then writes a prescription for N that the sprayer applies in real-time. Readings are averaged across the swath width and N recommendations are based on in-season yield potential and the responsiveness of the crop to additional N. This real time integrated optical sensing and application system measures crop status and variably applies the crop’s nitrogen requirements. The GreenSeeker is opening a new window of nutrient application timing in corn, beyond waist height. The system is designed to apply the right amount of N at the right place at the right time, increasing yield and reducing environmental N. For more information on the SoilOptix™ system or the GreenSeeker, visit practicalprecision.ca. |

This project was funded in part through Growing Forward 2, a federal-provincial-territorial initiative. The Agricultural Adaptation Council assists in the delivery of Growing Forward 2 in Ontario. Industry collaborators on this project include Practical Precision Inc., Hensall Co-Op, Underhill’s Farm Supply, and Claussen Farms. •