Improved stress tolerance

ACHIEVING OAT KERNEL FILL

IT IS COMMON knowledge that stressed plants will not achieve optimum performance or yield. But what does stress actually do to a plant? New oat research results have found a direct link between how plant stress limits kernel fill and reduces yield. And the results could lead to the development of more efficient and effective oat varieties for Ontario farmers.

| WHAT YOU NEED TO KNOW • This study’s novel approach to determining how oat stressors impact yield will go a long way to help plant breeders develop more effective selection techniques. • Each kernel has its own ‘pipeline’ of nutrient requirements right to the main stem of the plant. • If a plant has 30 per cent unfilled kernels, a farmer’s yield is directly reduced by 30 per cent. • By deconstructing the panicle and measuring the kernels, McElroy was able to determine when the plant was stressed. |

Art McElroy, research coordinator with PhytoGene Resources Inc., recently wrapped up a two-year study evaluating how oat kernels fill and determining how plant stressors — disease pressures and environmental effects — impact the kernels, and ultimately yield. He started his research with the results from earlier oat studies where he noticed a strong correlation in yield to kernel weight in a well-filled kernel. McElroy believes changes in the kernel patterns suggest stress effects, and as expected, some kernels will not develop fully.

“It all comes down to grain development and kernel fill,” explains McElroy who, working with his son and fellow planter breeder, Michel McElroy, set out to develop a more refined, and less costly approach to oat breeding by selecting individual traits linked to yield, in an effort to combine the desirable traits in superior cultivars.

“Grain development is intricately linked to yield, kernel size, and test weight, that’s why grain development and kernel fill have been our focus for this plant breeding research.”

EVALUATING OAT KERNELS

Several parameters were used to evaluate grain development, and by extension, stress tolerance and susceptibility — including the number of kernels set, frequency of unfilled kernels and grain fill.

“There were three main ingredients necessary for this study — a large number of elite lines to provide a range of genetic backgrounds, several sites to offer different stresses, and the ability to evaluate all the oat kernels from the representative samples,” says McElroy.

It has been difficult to measure oat losses in the past because many oat kernels that are small or unfilled are often lost during combine harvest or at sample cleaning when they simply blow away. Traditionally, these kernel losses are not consistent across test sites, making it harder to collect accurate data. McElroy had his work cut out for him to find a way to collect and evaluate kernel losses because, he says, “these need to be retained because there is so much more to be learned about stress from poorly filled or unfilled kernels.”

The greatest challenge was to develop a device to measure kernel ‘size’. It is difficult to accurately measure kernel fill (which is directly linked to yield) because well- and poorly-filled oat kernels are almost the same width. However, thickness is related to kernel mass, so McElroy developed a device to measure kernel thickness rapidly and precisely.

“Grain fill, or the kernel thickness, is an excellent indication of plant stress,” he explains. “The number of kernel sets, unfilled kernels, and placement along the panicle can tell us at what point in the plant’s development it was stressed. This information can also help us understand grain development and genetic selection.”

Initial study results found that the number of kernel sets and the frequency of filled kernels are the two major factors affecting yield. McElroy says that both are determined very early in the growth cycle, at about the 4-leaf stage, and there was genetic variability for both.

The biggest surprise came from previous oat research that determined unfilled kernels were not ‘aborted kernels’ (a common understanding), since there was no flower development or pollination to begin with. This new finding means that existing kernels don’t benefit from any unused resources, like carbohydrates, from the unfilled kernels because each kernel has its own ‘pipeline’ of nutrient requirements right to the main stem of the plant. “Unfilled kernels represent a direct loss of yield potential,” says McElroy, explaining that, if a plant has 30 per cent unfilled kernels, a farmer’s yield is directly reduced by 30 per cent.

IN-FIELD TRIALS

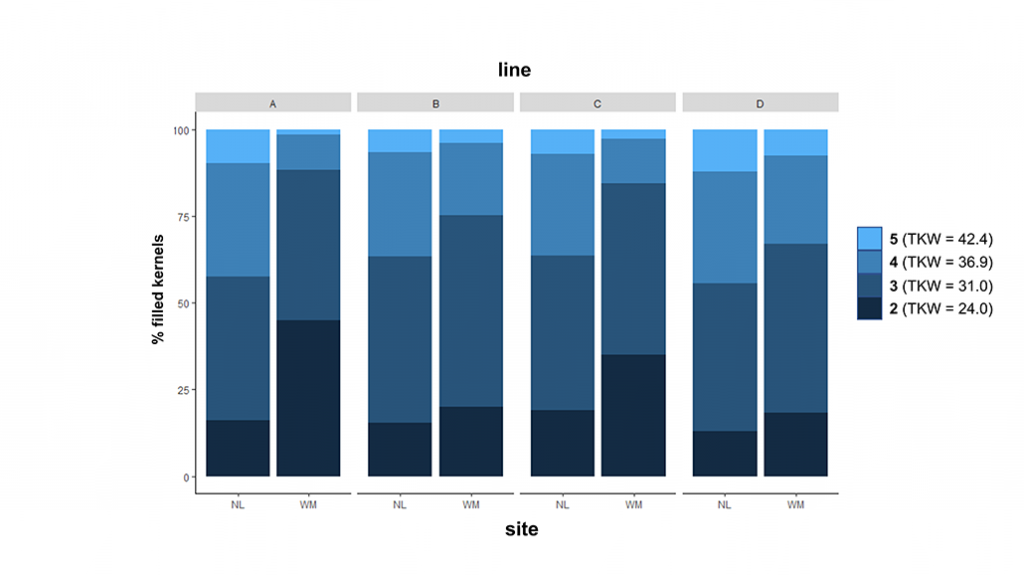

The in-field studies took place in New Liskeard, Ontario and Sainte-Anne-de-la-Pocatière, Quebec in 2019, and in New Liskeard and West Montrose, Ontario in 2020. Two tests of 36 entries (six check varieties and 30 advanced lines) were grown in standard plots, with three replications at each site. Prior to harvest, 20 panicles were removed from each plot for detailed analysis. McElroy explains that measuring grain fill can be challenging because kernel size, even under good growing conditions, vary considerably within a panicle.

“There can be a 10-day difference in flowering time from kernels at the top to the bottom of the panicle, and secondary kernels are always about 30 per cent smaller. So, if well-filled secondary kernels from the lower part of the panicle weigh less than a poorly filled primary from an upper node, how do we determine ‘who did their best and who didn’t’?” he says. That’s why the research required deconstructing individual panicles — more than 150 in total — to record the mass and position of each kernel. “This provided some very fundamental insights into grain development,” notes McElroy.

Through the research process, the question of how to determine if plant stress has affected the development of kernels with so much variation in weight and mass of each panicle was investigated. The answer was to look for differences in kernel thickness patterns. By deconstructing the panicle and measuring the kernels, McElroy was able to determine when the plant was stressed. “If it was stressed later in the season, we saw solid top fill and poorly filled kernels at the bottom,” he explains. This information was compared to rainfall data for each test site to confirm the timing of environmental stressors with the kernel fill results.

NEXT STEPS

This study’s novel approach to determining how oat stressors impact yield will go a long way to help plant breeders develop more effective selection techniques. McElroy’s novel approach to measuring plant stress response by determining kernel size distribution patterns and measuring kernel thickness is part of an ongoing effort to understand the genetic basis of factors affecting oat yield and quality.

“The results of this project will provide a more effective tool for plant breeders to select for specific stress tolerances, particularly those stresses that occur during the grain fill period,” says McElroy. “Ultimately, this information will create more stable, higher-yielding oat varieties for Ontario growers.”

Funding for this research was provided by Grain Farmers of Ontario, Cribit Seeds, and the Crop Development Centre (University of Saskatchewan). •