Cropside: Recirculating booms

AGRONOMIC INFORMATION FROM ONTARIO'S CROP SPECIALISTS

CONVENTIONAL BOOMS

Larger sprayers feature booms with five to 13 sections that terminate in caps (or valves for flushing). Pressurized liquid is fed to the middle of each section and must exit at the nozzle or the boom end. This design has issues that complicate cleaning, create waste or contamination, and take time. Specifically:

- To prime the boom with product before spraying we must first spray or drain any existing water or product.

- To clean or flush the boom we need to displace the existing liquid.

- Section ends require special care to flush.

RECIRCULATING BOOMS

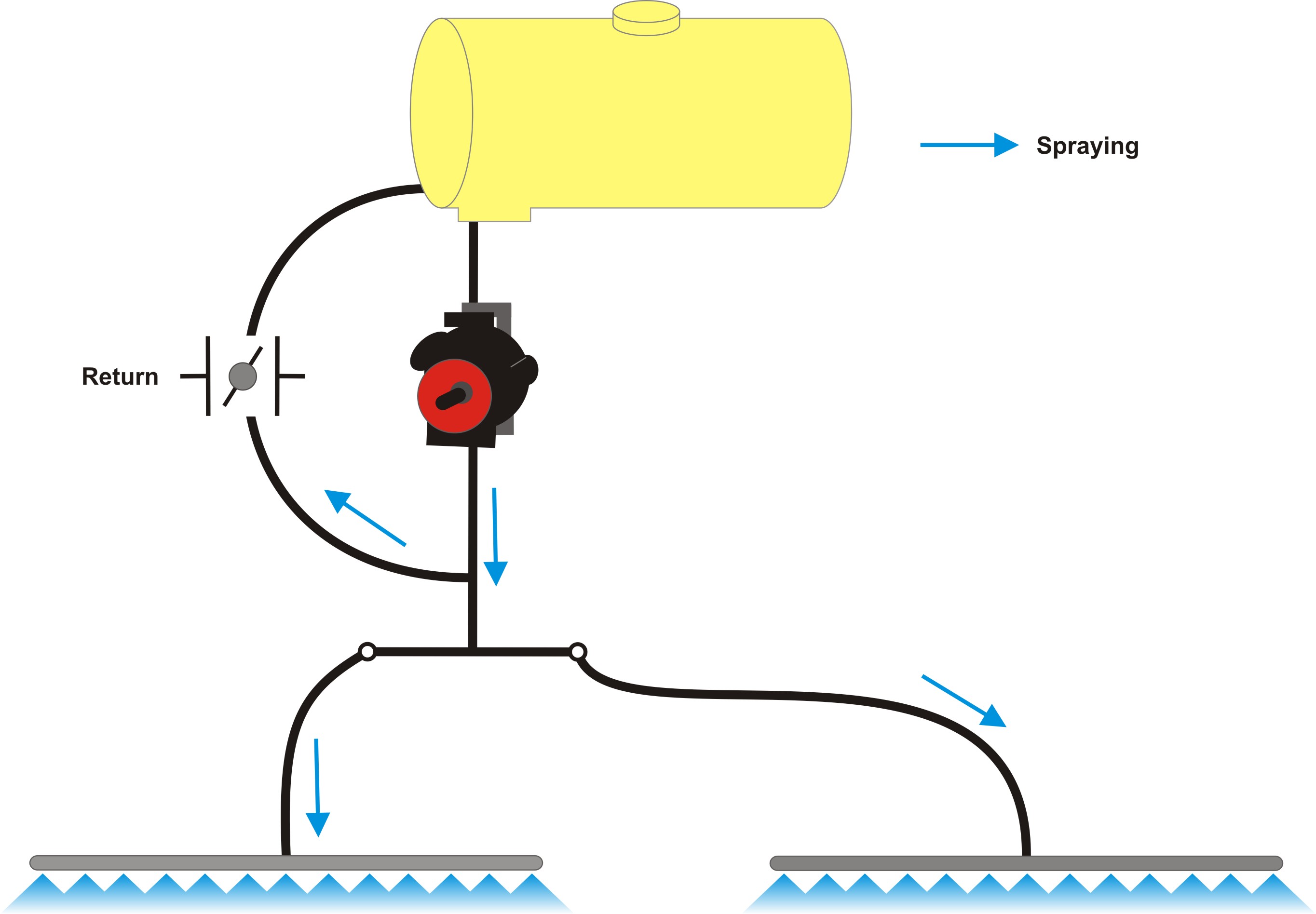

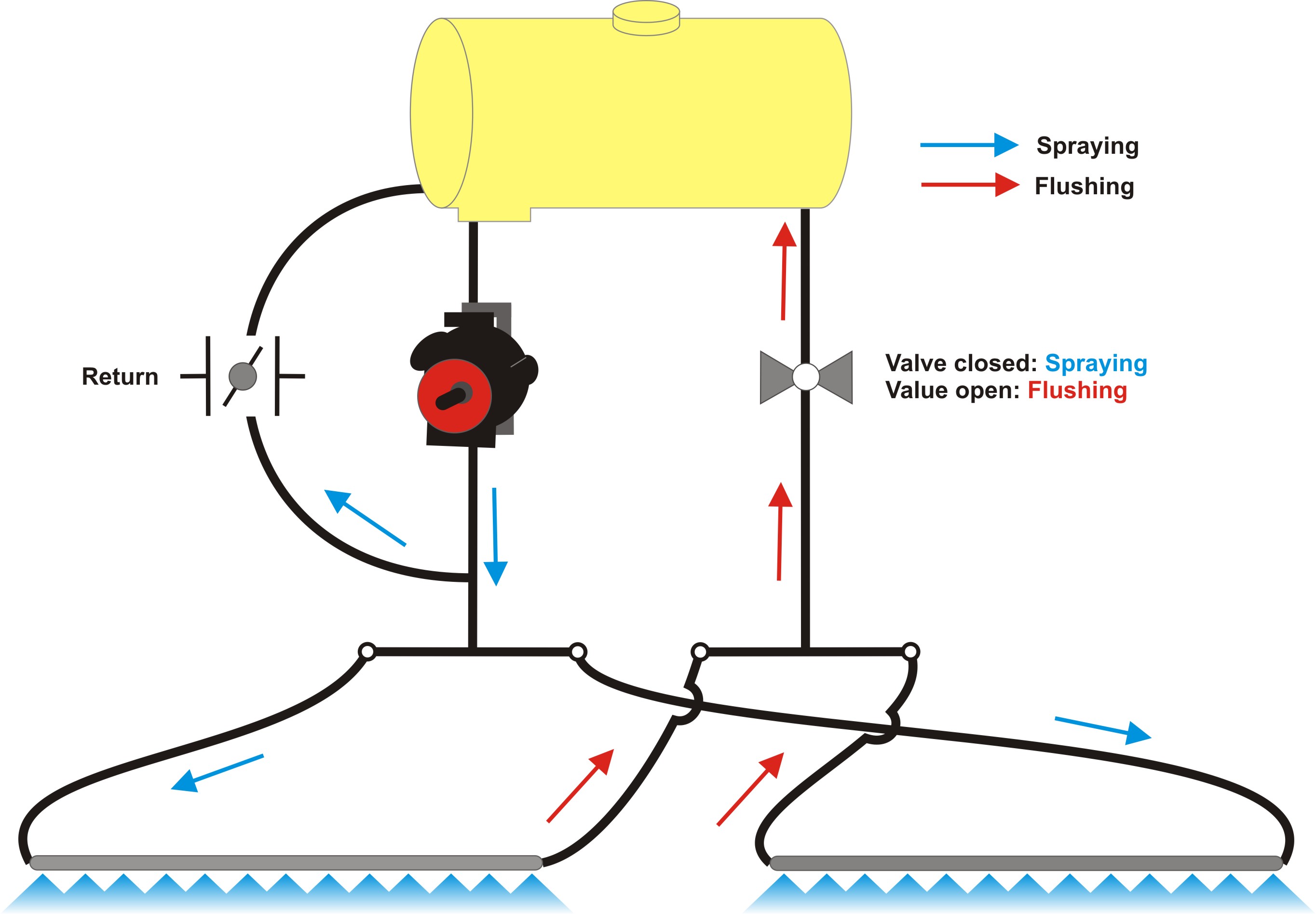

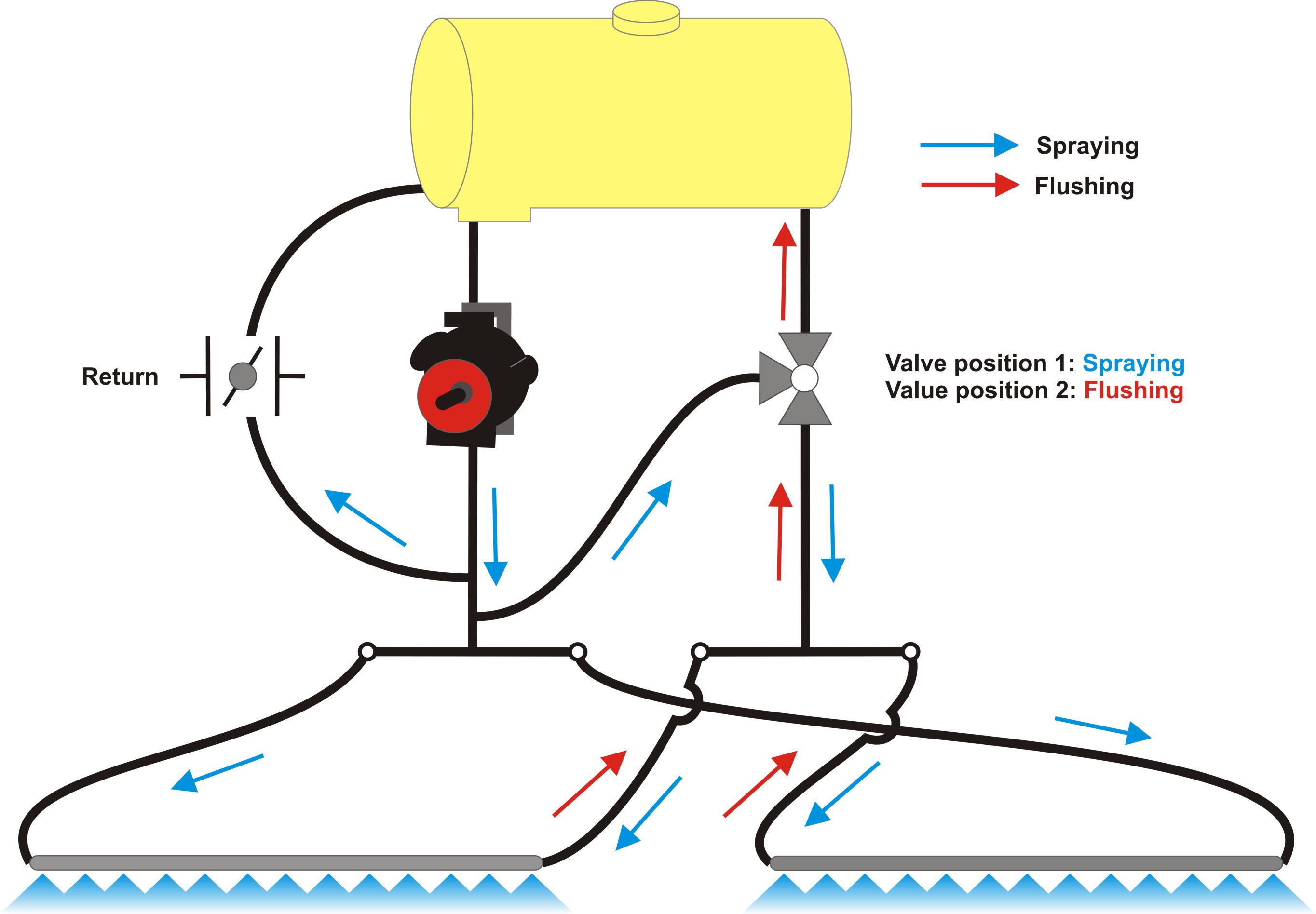

In a recirculating boom, spray mixture enters the boom at one end and exits at the other, returning to the spray tank. In most cases, the left and right wing each has its own feed and return. Sectional control is achieved via individual valves (air or electric) on the nozzle bodies. There are two types of recirculating boom available:

Type 1 – During spraying, flow is routed into the boom and the returns are closed. When nozzles are shut off (perhaps for a turn) the return opens to route flow back to the tank. Examples include Pommier and retrofits such as Pentair’s swept flange boom ends which replace end caps.

Type 2 – A 3-way valve is connected to the return and the pressure side of the pump. Now flow can return to the tank (like Type 1) or can be pumped into the boom from the return side to pressurize the boom from both ends. This is particularly useful on longer booms (combatting pressure drop) or when high flow is required. Examples include Agrifac sprayers, RoGator’s C series (Liquid Logic), and the Canadian prototype Connect sprayer from Pattison Liquid Systems.

BENEFITS OF RECIRCULATING BOOMS

- Simplify the boom cleaning process.

- Opportunity to graduate to a better-resolved sectional control (because individual nozzle shutoff valves are required).

- Save spray mix during priming or when rained-out.

- Save water during rinsing (as much as 30 U.S. gallons per prime).

- Prevent soil and water contamination from repeated priming.

- Reduce nozzle plugs through repeated spray mix filtration.

Recirculating booms remove many of the contamination problems associated with conventional plumbed sections. They save time, money, and reduce environmental impact. These systems will be demonstrated at Canada’s Outdoor Farm Show.