Wheat blending

ADVANTAGES FOR ONTARIO MILLERS

FLOUR MILLING COMPANIES are always looking at ways to make the best quality flour for the lowest possible cost, and there are different ways to try to achieve this. Maximizing on automation in the production facility to reduce the cost of manpower can help in medium to long term savings, while some more immediate measures such as reducing the cost of materials required in the production of flour is also considered. For mills producing wheat flour, wheat is at the top of this list, and mills are forever looking at ways to reduce this expense without sacrificing on quality and milling efficiency.

| TERMS Absorption – the amount of water able to be absorbed by the flour to form a dough of a defined stiffness. Measured as the percentage of flour weight. Farinograph stability – measures the timeframe which dough can be mixed and remain at a certain stiffness/strength before it breaks down and becomes too soft. Gluten strength – a general term used to describe the overall elastic and extensible properties of dough due to the gluten present. Sufficient gluten strength is required for baking the majority of common breads. Loaf volume – the size of the loaf of bread measured by total volume after it cooled for |

There are many different classes of wheat for mills to consider purchasing to produce the quality of flour required of their bakery customers. Canadian Western Red Spring (CWRS) wheat is the most popular of all wheat classes grown in Canada and known worldwide for its high protein content and superior gluten strength desired for the production of breads such as pan breads and artisan-style loaves. This makes CWRS one of the higher priced wheat classes to purchase. In addition, the mills in Ontario have the added cost of freight costs to move the wheat across the country.

Canadian Eastern Hard Red Spring wheat is also a good quality wheat for producing bread flour for similar products but there simply isn’t enough of it grown in Ontario to meet their demand.

Canadian Eastern Soft Red Winter (CESRW) wheat is the most common wheat class grown in Ontario. It is best suited for bakery products such as cookies, pie crusts, and crackers. It has lower protein content and this allows for the delicate texture these products are known for. Unfortunately, this is not ideal for breads requiring high protein.

At current commodity prices, and as is the case most of the time, CESRW is traded at a lower price than CWRS. This leads to the question of whether the addition of CESRW wheat would impact quality when added as part of a blend with CWRS wheat.

The addition of CESRW wheat to a blend consisting mostly of CWRS wheat would reduce the cost of the wheat blend but this option could only be considered if quality is maintained for bakery customers.

TESTING THE BLEND

An experiment was performed at the Grains Analytical Testing Laboratory, a joint venture between SGS Agriculture and Food and Grain Farmers of Ontario, where CESRW wheat flour was blended with different ratios of CWRS flour, and then compared to the 100 per cent CWRS wheat flour to see if there were any impacts on quality.

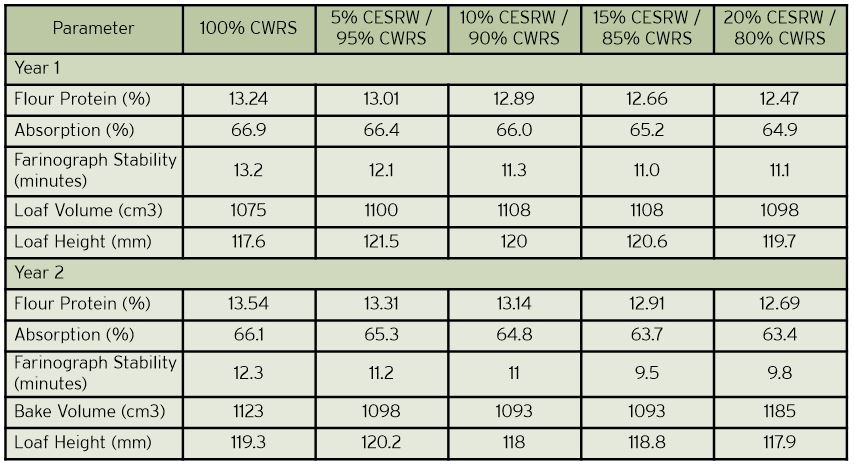

Flour, dough, and bake tests were performed to evaluate the impact at each of those blends, and then repeated the following crop year to account for environmental differences in wheat growing seasons which can impact quality. The chart summarizes a few of the key quality parameters and their results.

The expectation of including more CESRW flour would be lower flour protein and water absorption. This ultimately would affect the resulting gluten strength and baking performance once the ratio of CESRW got too high.

RESULTS

The impact of the five per cent CESRW / 95 per cent CWRS ratio on these parameters was slight and still resulted in an industry acceptable bread flour. In the first year of testing, the bake volume was noticeably improved with the five per cent CESRW / 95 per cent CWRS blend, and similar to the 100% CWRS for all the others. In year two, although the bread volume was not larger than the 100 per cent CWRS, the five percent CESRW / 95 per cent CWRS was very similar.

As the ratio of CESRW flour increased beyond five per cent, there appeared to be some noticeable affects to some of the quality attributes when compared to the 100 per cent CWRS flour. Water absorption and protein content of the flour was noticeably lower, and gluten strength dropped as well — as identified by the Farinograph stability parameter.

The Farinograph stability is one of the common parameters used in industry to measure gluten strength. Higher values indicate the ability of a dough to withstand the impact of mixing over longer periods of time before the gluten begins to break down. There are indications that the addition of up to five per cent CESRW to CWRS flour wheat seemed to have only a slight decrease on the Farinograph stability, but flour blend rations which included 10 per cent or more CESRW flour showed more significant decreases in both years.

Even though the protein content of the CESRW flour was much lower than the CWRS flour, the effect on the overall content of the five per cent CESRW / 95 per cent CWRS flour ratio was not significantly affected. With regards to quality, the flour and bread did not seem to be impacted.

As for financial impact, it may seem as though the addition of only five per cent CESRW to the wheat blend producing bread flour is insignificant, but the impact on the wheat cost over the span of a fiscal year for a large commercial flour mill in Ontario can result in huge savings when you consider some of the larger mills process more than 100,000 metric tons per year. This concept shows great promise as a cost saving opportunity, with little to no affect on quality, and something for millers to consider.

This article features an initiative of Grain Farmers of Ontario’s Market Development department.

Paolo Santangelo is the commercial manager of the Grains Analytical Testing Laboratory, a joint venture between Grain Farmers of Ontario and SGS Agriculture and Food. For more information on this study, please contact him at paolo.santangelo@sgs.com. •