Strip till residue

AGRONOMIC INFORMATION FROM ONTARIO'S CROP SPECIALISTS

STRIP TILL

Strip till requires a no-till residue management mindset. Strip till is promoted for the ability to achieve the productivity and soil condition benefits of conventional tillage while realizing conservation benefits of no-till. While conventional tillage may hide poor residue management, strip tillage does not and requires residue management considerations of no-till.

Residue management starts with uniform residue and chaff spreading of the preceding crop. Like no-till, strip and crop performance suffers where residue, chaff, or volunteer cereal concentration is excessive. Most modern strip tillers include some form of row cleaner, critical for removing residue from the row area to make a clean tilled zone, beneficial for soil warming, drying, and preventing residue incorporation into the seed zone. While important, they are not a replacement for poor residue management.

Heavy chaff and root structure of dense volunteer cereals in chaff rows can impair strip tiller performance, even with more aggressive strip tillers with row cleaners under good soil conditions. Strip performance is even more difficult under damper soil conditions. Soil is often not sufficiently worked as root structure of volunteer cereals “ribbons” soil instead of breaking it into chunks or aggregates, and chaff can often be heavily mixed into the strip. Where cereal straw is windrowed for baling, chaff should be spread if possible, or volunteer cereals controlled early.

A TEST CASE

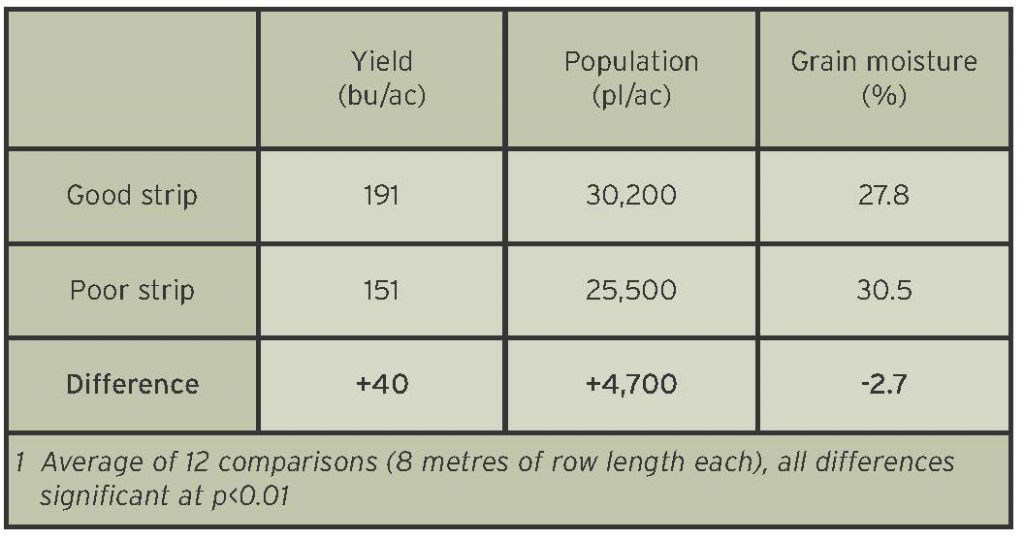

While more extreme than most cases, a trial was completed on a heavy clay where straw was windrowed and baled before strip tilling in August. A shank-style strip tiller with row cleaners was used. Despite dry conditions, strips on old windrows, heavy with chaff and volunteer wheat seedlings, did not work up and instead ribboned out soil from the shank (Fig. 1). Corn in these poor strips was clearly affected the following spring (Fig. 2) and the farmer wondered about yield impacts. Hand harvest comparisons were made between poor strips and good strips a couple rows away. The poor strips in this field yielded 40 bu/ac less than good strips (Table 1). Assuming one corn row is impacted by chaff rows every 35’ in this field, this represents seven per cent of rows, or three bu/ac yield loss overall. At $5/bu, this represents a penalty (or budget to improve residue management) of $15/ac. •