Compaction action

ARE YOU TRYING to choose between tracks or tires on your farm equipment? Each has specific advantages but the best all round solution may be difficult to determine for individual operations.

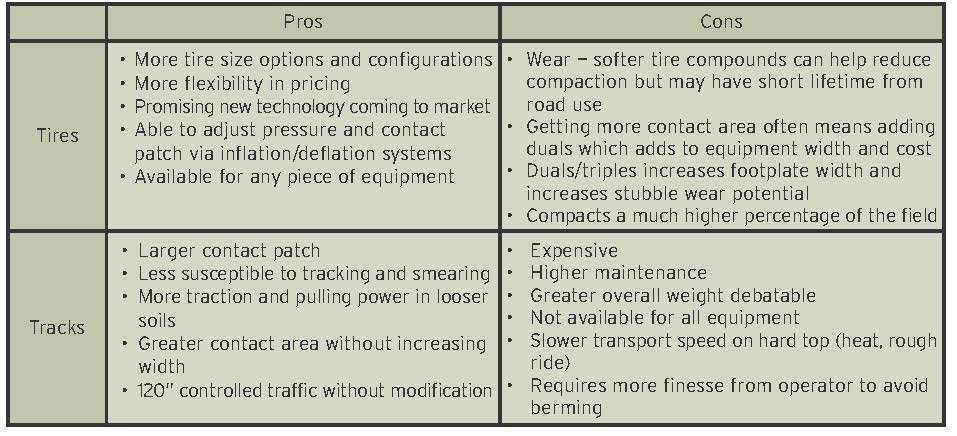

It is important to look at all the questions in the decision to equip tractors and larger farm equipment with tires versus tracks (Table 1). Some of them are economic, others logistical, and others related to soil compaction. In the end, the decision has to be made based on the impact of the combination of pros and cons on your farm.

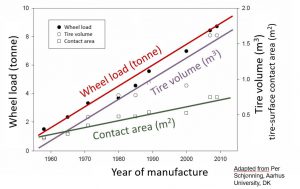

The reason why there has been a move to tracks as an alternative to tires, especially for large farm equipment, can be explained by Figure 1. Looking at the history of overall equipment weight for tractors, it has increased steadily since the 1960s. While tire volume has kept up for the most part due to using taller and wider tires, the overall contact area on the ground has not increased at the same rate. This means that the weight per square inch being carried by tires has increased significantly.

At the same time, farm operations have changed with the changes in livestock production, a reduction in crop rotations, and the use of perennial forages in crops. These are a few of the simple reasons why compaction has increased over time.

There are three ways to get bigger contact area out of farm equipment tires: use taller and /or wider tires; use more tires (duals or added axles); lower tire inflation pressure.

The alternative option, which a significant number of people have chosen, is to replace tires with tracks. A 36 inch wide track with six to 20 feet of track length, quickly achieves a lot of contact area.

COMPARISON

In reality, the choice is never that simple, particularly if reducing compaction is a primary goal. During the Innovative Farmers Association of Ontario (IFAO) Compaction Action event, we compared two similar articulated tractors, one on tracks and the other with duals.

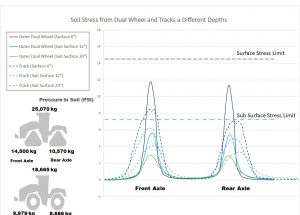

The 450 Quadtrac Steiger tipped the scales at 25,070 kg (55,154lbs) with 14,500kg on the front axle and 10,570 on the rear.

The 470 Steiger weighed in at 18,665 kg (41,063 lb) with 9,979 kg and 8,686 kg on the front and rear axles respectively. Both of these machines were unballasted, but the tracked machine weighed six tonnes more. The wheeled machine was sitting on 480/80 R50 duals on all corners, 16psi in the front, 13 psi in the rear (set for road travel). The tracked machine had a 30 inch wide by six foot long track (depending on how you measure them). Nebraska Tractor Lab reports a 29.5 inch contact length on hard ground. This is by design for these tracks to increase maneuverability on the road.

For compaction testing, sensors were buried into the soil at six, 12, and 20 inches. The sensors were about six inches wide and inserted into the undisturbed ground from an adjacent excavated soil pit. Each piece of equipment crossed the sensors several times.

The sensors measure ‘soil stress’ at each target depth. This stress value has been calibrated over many test runs in Europe to be a proxy for compaction potential on an average soil under average conditions. Keep in mind that results can vary widely as conditions change. For risk to compaction potential, on average, the thresholds have been found to be 14.55 psi for topsoil and 7.25 psi for the subsoil. The data from the two machines are shown in Figure 2. The results were not as clear cut as one might hope.

The topsoil pressure was reduced by about four psi by the tracked machine, even though it was 6,405 kg heavier. This is due to the increased footprint of the track compared to the contact patch of the duals which were inflated to road pressure. There may be a slight reduction in surface pressure if the tire pressure was decreased for field work. Setting the tires for six miles per hour, the tire pressure could be set near nine psi for the duals.

Deeper in the soil, (12” and 20” depths) the sensor pressure readings were very similar. The extra weight of the tracked machine is carried by the subsoil. This was somewhat anticipated as axle weight is a key component in deep compaction. The results suggest the tracked machine may leave a better looking track in the field, but the damage done deeper in the soil may be similar.

WEIGHT

If you were wondering, “Who is going to operate the wheeled machine unballasted?”, you may have a point. Conventional wisdom would suggest that for the two tractors to be equal they should weigh the same. Nebraska test lab reports for the 470 Quadtrac and the 470 Wheeled Steiger indicate very similar drawbar performance for both machines with a slight advantage to the tracked machine especially at lower speeds. The 470 Quadtrac and the 450 Quadtrac use the same frame and tracks but the 450 has less horsepower, so to compare equally, the report for the 470 Quadtrac was used. The heavier tractor will be able to pull harder, plain and simple, but there is a point where too much extra weight causes a shortage in horsepower. The wheeled machine, as it is unballasted, will be slip limited. Adding more ballast to the wheeled machine will help increase drawbar pull at low speeds, but will limit efficiency at higher speeds.

Traction efficiency is the ratio of drawbar pull to vehicle weight. Traction efficiency for tracks and tires is relatively the same on firm untilled soil, but where soil is weaker; there is a likely advantage to tracks. Adding weight to the wheeled machine would have the effect of increasing ground pressures, which is true. Remember though, that we can still reduce the ground pressures for the wheeled machine by adjusting the tire pressure for field work.

Wheeled machines have been shown to be most efficient when the weight is 2.5 times the drawbar load and tracked machines can be most efficient at two times the drawbar load. This is a simplification of a much broader topic of setting ballast and axle weight for optimum efficiency, but the take away is that a tracked machine can get more drawbar pull for the same weight and horsepower. Again, adding to this complex topic is tire pressure. For an overinflated tire, when the drawbar load exceeds 40 per cent of the machine weight, tractive efficiency (power to the ground) can be reduced significantly. For drawbar loads below 40 per cent of vehicle weight, there is no significant loss in tractive efficiency, but the overinflated tire is not helping you reduce compaction at any load.

From a soil compaction point of view, what we saw at Arthur suggests that for the two machines setup for road travel and unballasted, there was a slight reduction in surface pressure for the tracked machine even with six tonnes of extra weight. Other than that, the risk for causing surface compaction for those field conditions was low; however, sub surface soil pressures were nearing the threshold for both tracks and tires.

What we can say from looking at other research is that tracks can provide higher traction efficiency in looser soil conditions compared to the wheeled machines, but these soils may be at higher risk for compaction. Since we only did tests in one soil condition, it is impossible to say that the two machines would have similar risk in all soil types or under different soil moisture conditions. There may be an advantage to having a six tonnes lighter machine, but with the data we have so far, it is still too close to call.

Consider a situation where you have to do some heavy pulling work and you have to pick between the two tractors discussed. Some questions to consider.

- Do you have to travel on the road a lot? – Depending on the roads in your area, there may be some advantages to either tracks or duals on the road. Tracks are narrower, but may take more fuel compared to wheels on the hard surface.

- What are the field conditions? – If field conditions are on the wetter side tracks may be the better option to avoid leaving a track but you still have to consider the total weight of the tractors. If it’s dry and you can set the tire pressure for the field it may be better to choose the overall lighter machine with tires. It still is important to have patience for when the ground is in suitable condition to carry the weight of equipment. Wet soils are the biggest factor in the occurrence and severity of soil compaction. Just because you “can go” doesn’t mean you “should go”!

- Are you able/willing to change tire pressure between field and road to optimize tires for the conditions.

- Are you willing to do the extra maintenance required with tracks?

- Can you put a dollar figure to the extra cost of tracks over tires in terms of the footprint in the field, the increased fuel cost with tracks, the potential for reduced compaction with tracks etc.

This article is part of a series highlighting lessons learned from the IFAO Compaction Action Day. Demonstration results, detailed demonstration set-up information, and a series of videos featuring the experts and topics from this day can be found at www.ifao.com. •