Compaction action

THE PICKUP TRUCK has been a vital piece of the equipment inventory on farms for decades, but oh has it changed. Think about the 1960s half ton fleetsides, with two wheel drive, three on the tree standard transmission, and that plastic bench seat. Typical farm pickups of the era weighed 3,400 pounds (lbs) curb weight with a payload of 600 lbs to 1,450 lbs. Four wheel drives were available as well as 3/4 tons, but they weren’t as typical on farms at the time.

Today, we see mostly 3/4 ton or better with curb weights of 6,400 lbs and payloads of 3,000 lbs with towing capacity exceeding 12,000 lbs. Add in six to 10 speed automatic transmissions, four door cabs, 17 – 20 inch rims, and sophisticated four wheel drive systems, and these are not your typical farm pickups of a bygone era.

Where you can go with a modern pickup truck is essentially anywhere! The question comes down to, should you?

Who in the 60s and 70s would have thought about driving a loaded pickup across freshly cultivated ground that was anything but bone dry? The pickup of the era was really about getting stock to market with a set of racks on the bed. Everything was close when farms were typically 100 acres, with all the fields out the back lane and easily accessed by the ole tractor and implements. Planters, sprayers, spreaders were filled at the buildings and driven to the field behind the 40 horsepower tractor. Today, pickups are in and out of fields under all conditions with hardly a thought to how amazing that is. They haul people, seed, tools, fuel, fertilizer, and chemical to distant fields and commonly are driven across fields. Even more common today is pickups hauling trailers, seed tenders, water tanks, and combine headers into and across the field.

IMPACT

During the Innovative Farmers Association of Ontario (IFAO) Compaction Action event, the planning group thought it was important to look at the impact of a current typical pickup truck on compaction. The results were compared to other farm equipment that is normally associated with compaction such as grain buggies, manure tankers, and big sprayers.

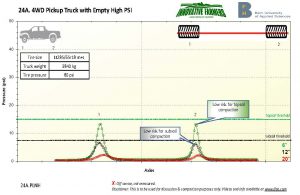

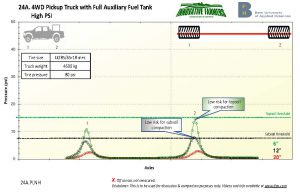

The vehicle tested was a late model RAM 2,500 HD four wheel drive. This truck was a standard cab and had LT285/65R18 M+S tires at 80 psi. The truck was equipped with an auxiliary 350 gallon fuel tank. It was compared with this tank empty and full. The truck weight with the auxiliary tank empty was 7,672 lbs and when full, 10,141 lbs.

The compaction demonstration was setup with buried sensors at six, 12, and 20 inches deep. The sensors were about six inches wide and inserted into the undisturbed ground from an excavated soil pit. Each piece of equipment was run across the sensors several times.

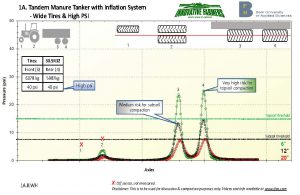

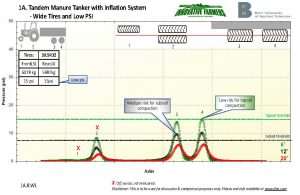

The sensors measure soil stress at the target depths. This stress value has been calibrated over many test runs to be a proxy for compaction potential on an average soil under average conditions. Keep in mind that results can vary widely as conditions change. For assessment of the risk of compaction potential, on average, the thresholds have been found to be 15psi for topsoil (six inch probe, the green line) and 7.5 psi for the subsoil (the black line) (Figure 1).

From Figure 2 note that while unloaded the pickup’s tires were below stress threshold for both topsoil and subsoil. However, when the auxiliary tank was full, the back tire was right at threshold for both depths of soil (Figure 2). Think about what the result would be if a skid of seed or a tote of herbicide was also in the bed of the truck.

To put this in perspective, we compare the truck to a manure tanker that you would normally associate with causing compaction. Referring to Figure 3 and Figure 4 you can see that a 5,000 gallon manure tanker weighing 30 tonnes equipped with 30.5R32 tires at 40psi, caused substantially more compaction potential.

However, when that tanker was equipped with an inflation/deflation system so that the field tire pressure was reduced to 15psi, the compaction potential of the 30 tonne implement was similar to a five tonne pickup trucks potential for compaction. From the chart you can see that this is just at threshold in both cases, so it’s prudent to think about how heavy your pickup is and where you are going with it.

This article is part of a series highlighting lessons learned from the IFAO Compaction Action Day. Demonstration results, detailed demonstration set-up information, and a series of videos featuring the experts and topics from this day can be found at www.ifao.com. •