Cropside: Nozzle strainers

AGRONOMIC INFORMATION FROM ONTARIO'S CROP SPECIALISTS

THE LEVEL OF sprayer filtration required for any given operation depends on a lot of variables. Potentially, you have opportunities to install filters at the tank opening (a basket), the suction-side of the pump, each section line, and behind the nozzles.

Horticulture or board acre, I’ve yet to see an operation that uses all four, but the suction filter and line filters are, to my mind, bare minimum. When I ask why operators don’t use nozzle strainers, the response is either “Because they plug” or “It’s one more thing to clean”.

Well, if your nozzle strainers are plugging, it’s likely because you have an agitation or mixing issue further up the line. They can handle a lot before the spray pattern begins to suffer … but you do have to clean them regularly so they can continue their good work. Running water through them just plugs them further, so they have to be removed when you pull the nozzles for cleaning (and I’m sure you do that).

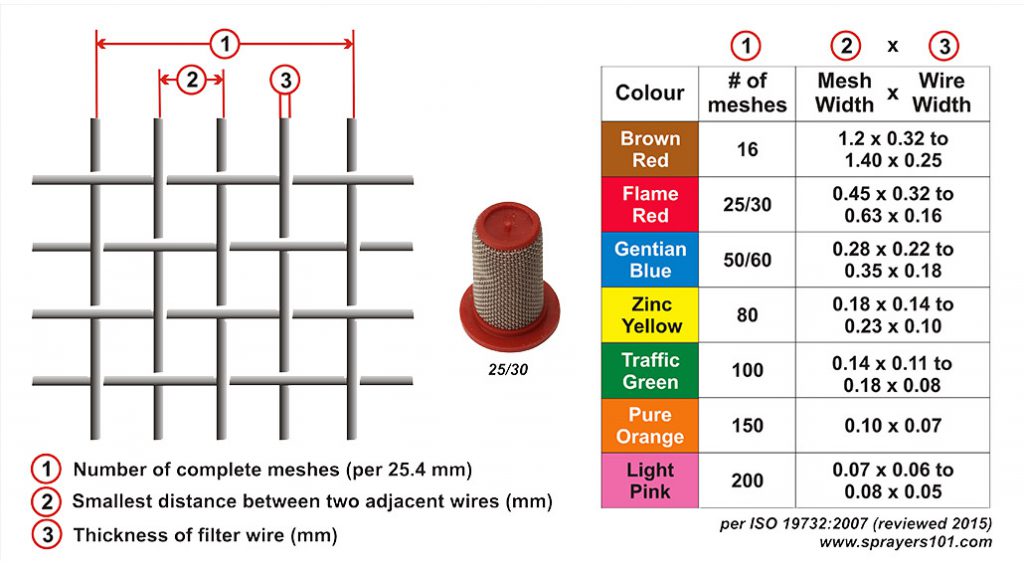

Each level of filtration should get progressively finer, with the nozzle strainers being slightly finer than the nozzle. Nozzle catalogues will often advise you on which to buy for the nozzle you are using. This infographic explains how nozzle strainers are classified.

If you use clean water, liquid formulations, and large nozzles, you may never need nozzle strainers. But, if you’re using dry formulations, if your agitation is under-powered, or if your fill water is less than pristine (I’ve found frogs in sprayers) then you might consider using them. •