Air assist

IMPROVED COVERAGE IN CORN

A FARM OPERATION near Dresden, Ont. bought a used 2010 Miller Condor with a Spray Air boom from Indiana. Their goal was to improve spray coverage in onion and tomatoes with the air-assist feature.

On June 19, the onion and tomato canopies were still too sparse to be a good testing ground (and the ground was very wet). So, the farmer and I decided to run coverage trials in a stand of three feet high corn on 30 inch centres.

The Spray Air boom features a series of air shear nozzles on 10 inch centres. A liquid feed line meters spray mix to the orifice, where high-volume air is directed at the flow via two cross-flow jets. This shreds the liquid into spray and shapes a 60 inch flat fan pattern. The operator can select from a range of air speed/volume settings that affect spray quality (lower air means coarser and fewer droplets and a smaller fan angle).

This particular boom also carried a set of hydraulic nozzles, so the operator could choose to turn off the Spray Air feature and employ a conventional application. This would be appropriate if applying a herbicide using air induction nozzles. In this case, the sprayer was equipped with TeeJet FullJet cones.

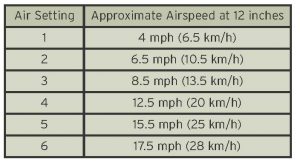

We measured the air speed produced by the boom. The operator moved between the six air settings in the cab, producing the following air speeds. Note that these speeds were much slower than the 100+ mph (160+ km/h) speeds noted in the Miller brochure. The owner has since told me that they found a number of air leaks in the boom that they have been diligently repairing, and as a result he is operating at a lower air setting.

We used water-sensitive paper wrapped around dowels to illustrate potential spray coverage. They were placed perpendicular to the spray at three depths in the corn canopy: high, middle and bottom. This provided an indication of panoramic coverage and represents a very difficult-to-wet target. Papers were later unfurled and digitally scanned. The papers were analyzed using DepositScan to determine the total per cent coverage and the droplet density.

Trials took place between 8:30 a.m. and 11 a.m. The temperature slowly climbed from 20º C to 23º C (~ 70º F). Relative humidity dropped from 69% to 60%. With the exception of Trial 1, we sprayed in a tail wind of 7.5 mph (12 km/h) gusting up to 10 mph (16 km/h). Travel speed was 7 mph (11 km/h).

In the first five trials, we made single, progressive adjustments to the spray settings that we assumed would improve coverage. Finally, we compared what we felt were optimal settings with the Spray Air (Trial 5) to optimal settings for the conventional hydraulic nozzles (Trial 6). Details are as follows:

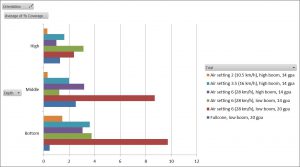

The following two graphs show the coverage obtained in the high, middle and bottom positions for all six trials. The first graph is per cent coverage, and the second is droplet density.

In Trial 1, the air was insufficient to properly atomize the spray mix (watch the video here: http://sprayers101.com/air-corn/) and this is evident in both graphs. By increasing the air in Trial 2 and Trial 3, we see that coverage increases in the high and middle positions, but declines a little in the bottom position. When we lower the boom closer to the canopy in Trial 4, we see increased coverage again in the high and bottom positions, but lose ground in the middle. We then increase our water volume for exceptional gains in the middle and bottom position, but at the expense of the high.

Throughout these changes, overall coverage trended up.

Finally, when we turn off the Spray Air system, and switch to the Fullcones, which were set to spray the same volume via the rate controller, there is a drastic reduction in coverage in all positions.

This leads us to conclude that there is an advantage to air assist in overall coverage and canopy penetration. Further, it demonstrates that such a system requires careful calibration to ensure it is being used optimally. Water volume, air settings, and travel speed should all be reconsidered when the environmental conditions change (e.g. temperature and wind) and when spraying different crops, at different stages of growth.

Jason Deveau is the application tech specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs. •