Port of Goderich

A GRAIN GATEWAY TO THE WORLD

GRAIN ELEVATORS HAVE towered over the town of Goderich for more than 150 years, taking in the local harvest, employing local citizens, and contributing to the local economy.

“The elevators are part of the fabric of who we are — and they make us unique in the area,” says John Grace, mayor of Goderich.

The Port of Goderich is the only deep-water port on the east side of Lake Huron, and today, the elevator’s capacity is about 125,000 metric tonnes or five million bushels of corn, soybeans, and wheat.

HISTORY

The first elevator got off to a rocky start. Originally built in 1866 out of wood, it burned to the ground in 1897. When the Grand Trunk Railway, which owned it, took no interest in re-building, local entrepreneurs and citizens stepped up to create Goderich Elevator & Transit, but once again, fire devastated the site in 1905.

Through a massive show of perseverance and will, the company built a concrete elevator that rose 150 feet in the air and held a half-million bushels of grain.

The next 40 years saw numerous upgrades. A facility that included a flour mill and grain storage was added by Western Canada Flour Mills in the early 1900s. The storage was eventually acquired and rolled into the Goderich elevator business when the mill stopped operating.

Parrish & Heimbecker (P&H) bought outstanding shares in the grain terminal in 2012 from then-owners Thirdcoast Limited. P&H is a Canadian business with 60 locations across the country focused on grain trading, handling, and merchandising as well as crop inputs, flour mills, and feed mills. It partners in Superior Elevator in Thunder Bay and has 15 inland facilities and four terminals in southern Ontario.

The Goderich facility is a mid-sized terminal operation in the P&H lineup.

TODAY’S ELEVATORS

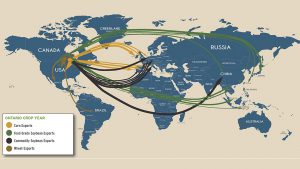

“The facility handles up to 150 trucks a day during peak harvest season,” says P&H’s Brad Wallaker. “Exports go to a number of destinations around the world, primarily the U.S. and Europe.”

Wallaker has been in the industry for more than 30 years and with P&H for 17.

The Goderich terminal also continues to handle and store wheat for the company’s flour milling divisions, shipped from Thunder Bay by self-unloading laker vessels.

“The newest of these vessels can carry close to 30,000 metric tonnes — that’s enough grain to fill 800 trucks,” Wallaker says.

Besides being a place of work and a repository for local grain crops, the massive elevators are also a tourist draw.

“People love to come and watch the vessels being loaded and unloaded,” Grace says.

There is a regular stream of outbound vessels and each carries between 12,000 and 21,000 metric tonnes of grain with a value of between $3.5 million and $12 million. Each can be unloaded in about 30 hours.

MOVING FORWARD

P&H is committed to the Goderich terminal, with a multi-million dollar investment underway in a new system that will increase the efficiency of ship loading, control dust better, and cut down on the amount of time needed for truck receiving and shipping.

“It’s all about handling the trucks more expeditiously,” Wallaker says of the progress that’s been made over his years in the business.

A total of 15 people are employed at the elevator. Wallaker says that between 500 and 600 trucks deliver grain directly from farms or from other grain handling facilities for each vessel loading at the facility.

The company has put in place windows of scheduling, along with specific commodity days to improve delivery experience. Farmers call the logistics department in Guelph to schedule a time — either mornings or afternoons or in one- to two-hour blocks.

They’ve also added technology that allows customers and truckers to get delivery transaction paperwork done without leaving the vehicle.

Wallaker says that last year was a ‘strong’ year in terms of export markets and demand, including soft red wheat, soybeans, and corn. He points out that volumes are not only dependent on local production, but also on world demand.

As of the end of July — given the volatility of what was happening with trade between the U.S. and China, and the condition of crops both north and south of the border, he was not willing to predict this year’s outcome.

“It’s anybody’s guess — what’s going to move and what’s not,” he says. •