Managing a late corn crop

HARVEST CONSIDERATIONS THIS FALL

SPRING 2019 WAS the latest corn planting for a large volume of the Ontario corn crop to date. We may have heard of a few corn fields that were planted in June over our career, but never at such a volume of acres as in 2019. In the past, a few acres of wet corn could be managed, but this year we will see an unprecedented amount of wet corn and a late harvest. The late planting of spring 2019 will have long term affects for everyone in agriculture and corn farmers will be dealing with it head-on this fall.

A factor we need to consider with our corn crop is maturity. Corn plants are deemed mature when sugar accumulation ceases to flow into the kernel. In a normal fall, that occurs when a plant forms the abscission layer where the tip of the kernel is attached to the cob. This is referred to as the black layer, also called R6 stage of development. Usually the grain is between 32% to 35% moisture at the time of black layer. At this stage it is normal for the plant to die back or have a frost hit it without losing any yield. If frost hits the crop before the black layer is formed, yield reduction will occur, and drydown will be more difficult.

CONSIDERATIONS IN DEALING WITH A WET GRAIN CORN THIS FALL

|

FROST DANGER

Research in the northern corn growing states has indicated that a killing frost (stalks and leaves affected) occurring at half milk line can impact yield by eight to 12 per cent. If it was a lighter frost just affecting the leaves, a yield reduction of five per cent was measured. You can judge milk line maturity by breaking a cob in half and looking at the difference between the soft milky tip and the hard starch cap of the kernel. Don’t look at the germ side of the kernel, look at the side of the kernel with the endosperm to measure milk line.

If grain maturity is just at full dent stage of the corn crop, we can expect to lose 23% yield to a killing frost or 12% to a light frost. If grain is dough stage (soft milky kernels) and just starting to dent, major yield loses will occur — 32% – 40% due to heavy frost and estimated at 25% for lighter frosts. Yield losses are attributed to low grain weight as reduced dry matter accumulation and will leave you with light test weight grain.

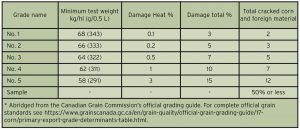

It is important to understand if your crop has naturally reached black layer before the frost, as a frost can also create a forced black layer due to plant death. In this situation, the kernel has not developed fully and will not have reached its full yield potential or test weight. The grain will be lighter in weight and will cause problems with harvest, storage, and marketing of the grain as it may not weigh up and will have grade discounts due to lower bushel weight (see table for details on grade based on weight).

Not all frosts are killing frosts and not all crops react the same. If your corn crop is close to maturity and has more leaf disease, a milder frost will shut down the remaining plant, while in a healthy green crop, the frost will only burn off the top leaves and will go deeper into the canopy on each following frost event. In the first case the crop will shut down and you will have what is left in the field at the time of the frost. In the second case, the plant still has green tissue and the plant will still transfer sugars and starch from the leaves and stalk to the ears. The healthy crop will continue to develop and increase grain matter until the final killing frost.

If you have immature grain on the plant, you will need to manage the crop differently depending on how the weather plays out. If rain occurs, you will notice the grain moisture increasing. On a fully mature black layered crop, moisture may hang but does not increase as rain events occur. The reason for this is that the abscission layer has not formed, and moisture will migrate from plant to ear. Choose dry days to harvest or wait for a freeze up.

HARVESTING

Complications in harvest attributed to early fall frost will be wet grain that doesn’t dry down like it should, and it could also cause trouble in shelling the cob and moving the grain. Combines will need to be adjusted as not to grind the grain and create more fines. Open the cylinder and check behind the combine to make sure proper shelling of the cob is occurring. Turn up the fan speed to blow out the extra chaff that is coming from the kernels being broken off. Good cleaning at the combine reduces the fines in the dryer and in storage, reducing the chance of fires in dryers and hot spots in bins.

Once grain is in the combine, wet grain will pile steeper and flow slower. Make sure you consider how the grain flows before everything gets stuck and plugged. Watch your rate of flow so your augers don’t plug. It’s better to take it a little slower than spend the rest of the day unclogging the system or repairing a broken auger. And always keep guards in place and do not have anyone start kicking the corn pile at the auger to get it moving, either in the combine, the grain buggy, or at the elevator — always put safety first.

DRYING

When drying, know the moisture going in and adjust the cycle times and temperatures to reflect what is being put through the system. Wet grain over 28% will be hard to accurately measure with portable moisture testers and will fluctuate greatly. For drying time, longer is better as the grain needs time to shrink the kernels to avoid fluffy hollow kernels. Fast, hot drying will not allow for kernel shrinkage and you will be left with a large kernel filled with air, which will result in lower test weight resulting in a lower grade and more deductions. Measuring grain moisture after drying may give inaccurate readings as moisture will continue to migrate to the surface of the kernel after drying. It is best to target moisture out of the dryer at 14% than have to re-dry after the grain acclimates. But the art is not to over dry or burn the grain as heat damage can cause grade discounts as well.

Everyone’s harvest timing will be different this year as it has been a variable growing season. Farmers will need to consider ground conditions and try to avoid compaction and rut creation. Harvesting before a snowfall to avoid field losses will also be a consideration that may cause wetter grain than ideal at harvest. If the decision is to harvest wet corn, manage the conditions you can control from harvest to selling.

This fall will be later, longer, and a lot slower. Be patient and be safe.

Marty Vermey is the senior agronomist at Grain Farmers of Ontario. •